Biomass Boilers Explained – What do You Need to Know?

Burning wood in order to heat your home may seem like a pretty old-fashioned idea, but modern technology has brought us way past the traditional open fireplace.

In the right circumstances, today’s bells-and-whistles biomass boilers can rival gas in terms of running costs – and potentially deliver a sustainable, low-carbon solution for your project.

What is biomass?

In basic terms, it’s any form of plant matter that can be burned to deliver heat. In practice, it’s normally wood.

This could simply be logs, or it might be a wood waste product (such as chips or pellets) that’s specifically suited to fuelling boilers. In addition, energy crops such as miscanthus are grown explicitly for use as a fuel – but these are typically only used for large-scale commercial operations as opposed to domestic installations.

If it is sustainably sourced, wood is considered to be a carbon neutral fuel, as the CO2 emitted from burning it is slightly less than the amount the tree absorbs as it grows. Unlike fossil fuels, wood produces negligible amounts of sulphur dioxide or nitrous oxides – so burning it does not contribute significantly towards the problem of acid rain.

In order to remain carbon neutral as a fuel, it’s important that the wood is grown as close as possible to where it’s used and that the local distribution system is efficient. Timber harvested for this purpose must be replaced, so that the equivalent CO2 emitted during combustion is reabsorbed by the new trees as they grow.

The OctoPlus biomass boiler from Solar Focus is available in 10kW, 15kW and 22kW

Wood chips are generated principally from forestry waste. Apart from being chipped and dried, they are not processed in any way. They are cheaper than wood pellets (per kWh of heat delivered) but not as cheap as logs.

Pellets, meanwhile, are manufactured from waste products such as ground wood chips, sawdust and bark, all of which are created by the timber processing industry. No chemical additives are needed as the natural lignin in the wood serves as a binder when the pellets are compressed.

How do biomass boilers work?

Fundamentally, they do the same job as conventional gas boilers, providing space heating and domestic hot water. There are a number of important differences, however.

Log boilers, for instance, have to be manually fuelled – so they’re not for everyone. They’re usually batch-fed, which means you fire the boiler at a high temperature for a relatively short period of time, and use this to heat a buffer tank that stores the warmth for later use in space and water heating.

This avoids the need for the boiler to operate 24/7 but there’s still a significant time commitment when it comes to firing up the appliance. Nevertheless, if you’re at home a lot and enjoy working with wood, it can be a great pleasure to run a log boiler.

By contrast, both wood chip and pellet fuels can be fed automatically, which means the appliance can be controlled in a similar way to a conventional gas or oil boiler.

This BioWIN 2 boiler from Windhager has a manually-fed pellet hopper

Wood chip is an option that’s normally used for commercial installations and other large systems, as the storage bin and feed mechanism take up a lot of space (with associated capital costs when they’re installed).

Given this, domestic biomass boilers are most commonly fuelled by wood pellets. This product has a low moisture content and relatively high energy content in comparison to its volume.

Typically, the compacted pellets are around 20mm long and 8mm in diameter. As they

have a higher energy density, you’ll need fewer deliveries and less space to store the fuel than you would with logs or chips.

The consistency of wood pellets’ size and moisture content makes them perfect for automated feeding and controlled delivery of heating on demand.

Pellets can be delivered loose, direct into a hopper, or supplied in sacks, which then need to be manually handled.

Biomass boiler size & maintenance

Calculating the right biomass boiler output and buffer tank capacity is a professional job and your installer will advise you on this – although there are ready reckoners available online.

In retrofit scenarios, the biomass appliance is often sized below the maximum system load, with the peaks being handled by the original fossil fuel boiler. This prevents biomass boilers running at less than full capacity (which would make them burn less efficiently).

When it comes to the maintenance side of things, all biomass boilers will need more attention than gas or oil boilers. They will produce a small quantity of ash – but the efficiency of modern units helps to ensure this is less than 1% of the volume of what’s being burnt.

If you have a garden, wood ash can be used as a fertilizer (as it contains potash). It’s also good for remedying acidic soils or simply adding to the compost heap.

You’ll need to clean the biomass boiler periodically, as well as regularly check the feed system for blockages and build-ups. Some units are largely self-cleaning, simply requiring you to empty the ash bin as and when it becomes full.

You’ll also need to have the chimney professionally swept, commission an annual service and ensure that the area where the fuel is stored is dry and well-kept.

How much does a biomass boiler cost?

Price will vary according to the type, spec, size and manufacturer. Domestic appliances can exceed £10,000 all-in – many times higher than the price of an equivalent gas boiler. However, payments from the Renewable Heat Incentive can offset this to a degree.

If you have mains gas available on your property, then it will be difficult to achieve a net drop in running costs – but by switching to biomass and using responsibly-sourced wood you’ll attain a saving in carbon emissions and contribute to reducing depletion of fossil fuels.

Logs can sometimes be had for free (if you have woodland on your site, for instance) – and this type of resource will warm you three times: when you’re cutting, splitting and burning it.

Pellets and chips are more expensive (both per tonne and per kWh of heat) as they’re processed products.

Bagged pellets cost approximately 6p per kWh; the alternative is a blown delivery, where a pipe attached to a tanker will blow the pellets straight into your storage area: a small delivery works out at around 5p per kWh. This compares to around 4p per kWh for gas.

If your installation is supported by the RHI subsidy, then the majority of the cost of the fuel will be covered, and you can start to make inroads on the capital costs.

You also need to be confident of having a long-term supply of whatever fuel you choose. Visit the NEF website for a list of suppliers in your area.

Renewable Heat Incentive tariffs for biomass boilers

Biomass boilers are one of the technologies supported by the domestic Renewable Heat Incentive (RHI) – alongside heat pumps and solar thermal panels.

This is not a grant scheme, but rather a steady stream of payments made directly to homeowners with eligible installations. Read our complete guide to the RHI for details of how to access the payments.

The exact level of Renewable Heat Incentive payments you’ll receive will be based on the head demand indicated in your Energy Performance Certificate (EPC). The cashback available for biomass boilers is currently subject to a cap of 25,000 kWh per annum.

Read our table to find out the latest Renewable Heat Incentive rates:

| Applications submitted before | Biomass boilers & stoves (p/kWh) | Air source heat pumps (p/kWh) | Ground source heat pumps (p/kWh) | Solar thermal (p/kWh) |

|---|---|---|---|---|

| April 2018 | 6.54p | 10.18p | 19.86p | 20.06p |

| January 2018 | 4.28p | 7.63p | 19.64p | 20.06p |

| July 2018 | 6.74p | 10.49p | 20.46p | 20.66p |

| June 2019 | 6.88p | 10.71p | 20.89p | 21.09p |

| March 2019 | 6.74p | 10.49p | 20.46p | 20.66p |

| October 2018 | 6.74p | 10.49p | 20.46p | 20.66p |

| September 2019 | 6.88p | 10.71p | 20.89p | 21.09p |

Based on a tariff of 6.74p/kWh, the maximum you could receive under the RHI is £1,685 per year (6.74 pence x 25,000kWh). Over the seven year duration of the RHI, this equates to a total possible payment of £11,795 – which would effectively negate the cost of installing the appliance in the first place.

However, bear in mind that many new build homes are so efficient that they don’t have this level of heat demand. So your actual payments could be significantly lower.

Is biomass energy right for my home?

These days, houses are designed to attain good standards of energy efficiency – so if you’re self building, look carefully at your predicted space heating demand.

In exceptionally efficient homes, it may be possible to attain desired comfort levels in a small dwelling with just a log-burning stove, especially if this is supplemented by a ventilation system that can distribute the warmth effectively. In such cases, it would be difficult to justify

the expense of putting in a complete biomass boiler system.

An alternative set-up is to use a woodburner with a back boiler, which could output to radiators. Note that pellet stoves with back boilers are eligible for the RHI, but models that burn logs are not (whereas both types of fuel are eligible if you’re using a full biomass appliance).

For years woodburning stoves have been hailed as eco-friendly, gaining a big following among the environmentally conscious. However, they have been embroiled in controversy as more local authorities across the UK opt for smoke controlled areas. Read more: Is your Woodburning Stove Eco-Friendly? |

Where biomass boilers make a lot more sense – both financially and in terms of reducing carbon emissions – is for larger new properties and existing buildings, especially homes that are off the mains gas grid.

You’ll need to ensure there’s sufficient storage space for your fuel and you need to be fit enough to handle it if you’re using anything other than a completely automated system.

Some appliances – especially log-fired batch boilers – also require an intermediate heat storage tank.

If you’re adding a flue or a fuel storage silo you may need to apply for planning permission or other consents in some instances – for example if you live in a listed building, conservation area or an area of outstanding natural beauty.

If you have the opportunity to set up a district heating scheme to supply several homes (as part of a community self-build group, for example) or a mix of domestic and non-domestic uses linked by a heat main, the installation might be eligible for the non-domestic RHI.

The payments are lower but the financial support lasts for 20 years. Bear in mind that metering is compulsory with this type of setup, which will increase initial costs.

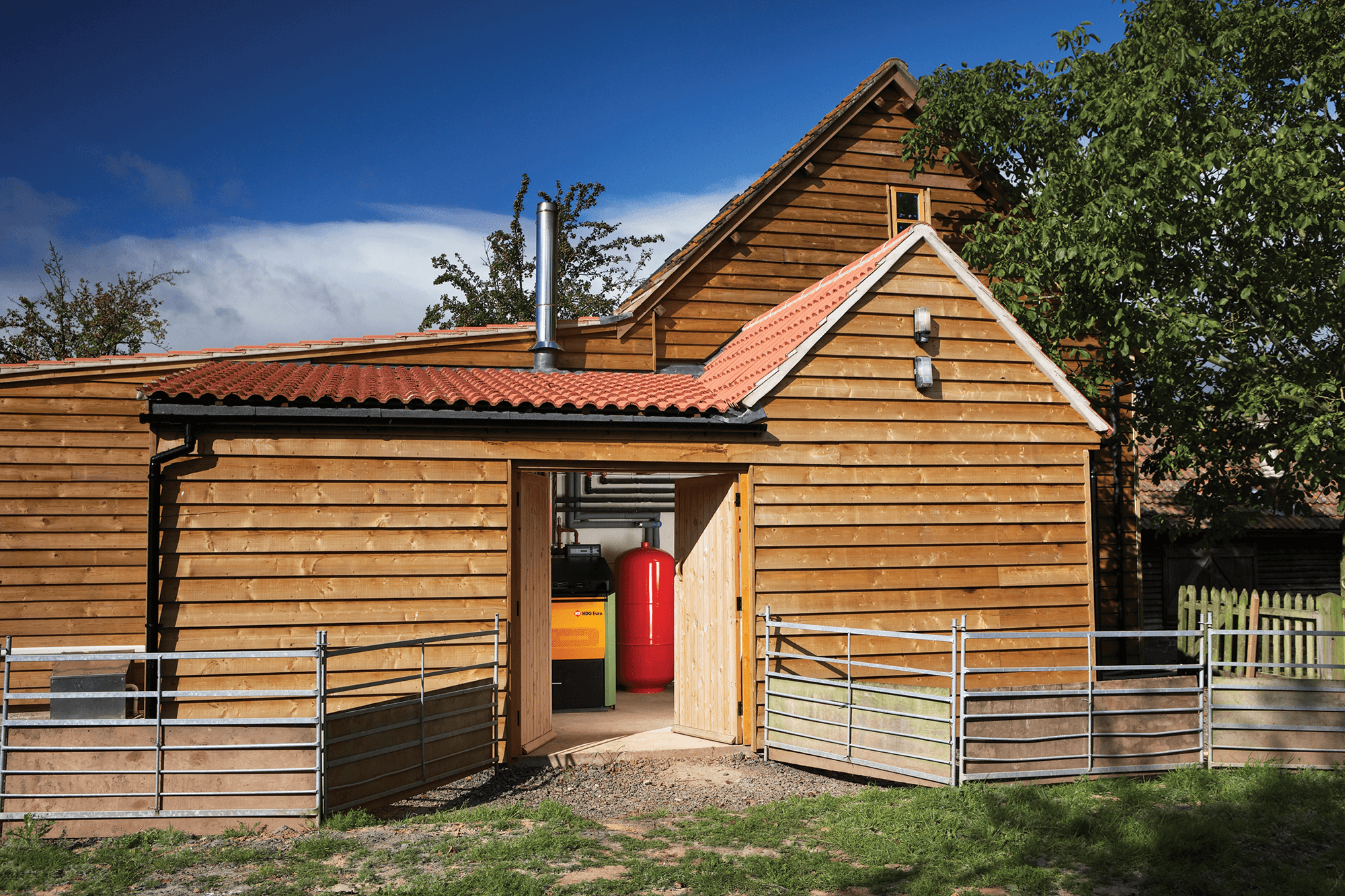

Main image: Large biomass boilers, such as this HDG Euro model from Euroheat, are best located in a dedicated utility zone

Login/register to save Article for later

Login/register to save Article for later

Comments are closed.