Ultra Efficient & Airtight Passive House Self Build in Perthshire

In 2007, Gordon Aitken completed his first bespoke self build in the Fife village of Leslie. With the help of his dad Bob (a retired builder) and brother Andrew (a joiner by trade), the high quality, low-energy eco house cost just £60,000 to build.

Now married with two young kids, Gordon and his wife Katie were looking to move from his previous project house as the family had outgrown it. They were also keen to relocate to the nearby Kinross area, to be closer to schools and amenities. Gordon’s long held ambition was to design, build and project manage a Passivhaus that would be their forever home. Finding the right plot, however, proved to be a long and frustrating process.

Securing the plot of land

Rather than looking for plots on the open market, the couple looked to get ahead of the competition by approaching landowners to see if they were willing to sell. “A few site negotiations had fallen through before we spotted this one for sale,” says Gordon. “It was a large, old portal frame farm shed that the farmer had been renting out and was looking to sell. I could see its potential.”

There was no outline planning for development at the time. “But I knew there was a good chance of getting a house built there as it would be part of a group of neighbouring buildings – it’s not an individual house in the country, which would have been trickier,” says Gordon. “The fact we were demolishing the old shed and rebuilding on the site, whilst retaining an original stone barn to the back, was viewed favourably by the local planners.”

On the south facing elevation there are larger triple glazed Velux rooflights for more solar gain

In February 2020, Gordon and Katie agreed to buy subject to obtaining planning approval and bought the plot that October. They sold their home in Leslie to fund the purchase and rented a property nearby for the duration of the project.

- NAMESGordon & Katie Aitken

- OCCUPATIONSSenior architectural technologist & NHS national improvement adviser

- LOCATIONPerthshire

- TYPE OF PROJECTSelf build

- STYLEContemporary

- CONSTRUCTION METHODTimber frame

- PROJECT ROUTE Homeowners designed & project managed

- PLOT SIZE1,008m²

- LAND COST£80,000

- BOUGHTOctober 2020

- HOUSE SIZE175m2

- PROJECT COST£281,000

- PROJECT COST PER m²£1,606

- VAT RECLAIM £26,601

- TOTAL COST £361,000

- BUILDING WORK COMMENCEDOctober 2022

- BUILDING WORK TOOK80 weeks

- CURRENT VALUE£415,000

Developing the efficient house’s design

Gordon, a senior architectural technologist, designed the couple’s new property. The scheme is based on the traditional Scottish longhouse and took some inspiration from local farm sheds. Its name, Bowhouse, is the old Scots word for cowshed.

Externally, the main part of the building features grey horizontal timber cladding and render. The pattern of glazing is designed to mimic a large barn door and openings. A utility room annexe to the back of the house echoes traditional offshoots on farm structures, with metal agricultural roofing.

The North Elevation can have the greatest heat loss, so features five layers of glazing and is a Passivhaus-certified product

The main roof is Spanish slate, with a heavier texture to reflect traditional Scottish slate. The grey timber cladding and natural vertical timber clad element on the upper level is Accoya – a treated timber that is pickled in vinegar and heat treated to change the molecular structure of the wood. This means it doesn’t rot and is very dense, giving it stability and longevity.

Gordon and Katie were keen to keep the finishes simple, with oak floors, white walls and with splashes of colour in the kitchen and bedrooms

“I used this finish on my first project, which was a great decision as it was so durable. Russwood manufactured the raw Accoya cladding profile and pre-painted it in the factory to simplify the installation process,” says Gordon. “I like the timber aspect of cladding design but I’m not so keen on the maintenance or the natural greying of Larch.”

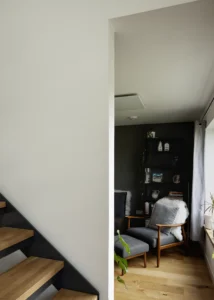

Inside, there are no corridors, just open-plan interlinking spaces that maximise room sizes. “Although, I have experience of drawing and detailing Passivhaus buildings, I appointed a specialist local consultant to guide me through the Passivhaus Planning Package (PHPP) and certification process,” says Gordon. “Es Tresidder from Highland Passive was very knowledgeable.”

Using a timber frame self build kit

The build started on site in March 2021. In terms of groundworks, originally they were going to have strip footings with a concrete slab on top. However, old rubble stone from a wall had been used as ground infill, meaning they needed to change their approach. “We installed a raft foundation, which worked out better as it’s more suitable for Passivhaus builds,” says Gordon. The property is built using a bespoke Scotframe kit with closed pre-insulated 184mm wide Valutherm timber frame panels.

Gordon, a senior architectural technologist, designed the couple’s new property. The scheme is based on the traditional Scottish longhouse and took some inspiration from local farm sheds. Its name, Bowhouse, is the old Scots word for cowshed

“The original timber frame kit erectors vanished three weeks before they were needed. We managed to get a backup team and the structure was up in three days with no problems, other than a slightly late delivery of the glulam ridge beam,” says Gordon. “Immediately after the kit was in place, I had an unplanned two-week hospital stay, but an architect friend kept things moving on-site. Katie also kept me up to speed with progress.”

With the structural shell in place, roughing joiners Kenny and John got started with installing the additional insulation, roof battens and sarking, external cladding, internal partitions, airtightness membranes and plasterboard. There is 100mm thick rigid wood fibre insulation installed over the first-floor walls and insulated roof panels, acting as a thermal bridge tea cosy.

CLOSER LOOKGordon and Katie wanted to optimise the design of the thermal envelope to eliminate thermal bridging and simplify the installation of the airtightness layer. In addition to the Scotframe Valutherm timber frame kit, they bolted on additional external insulating blocks made of wood fibre. These wrap around the whole first floor wall and roof structure, acting like a tea cosy on the outside of the kit. Adding the wood fibre keeps the house warm in winter, but it also delays summer heat from coming into the building as it doesn’t pass through the structure as quickly. “There was a heat wave when we were building and our traditional rental property felt really hot,” says Graham. “The new house wasn’t finished but we camped in it, as it was much cooler. So, as well as keeping the heat in, this process also keeps the heat out.” |

Sustainable Passivhaus design details

Gordon project managed the local tradesmen, including the roofers, groundworkers, plumbers, electricians and bricklayers, while getting heavily involved with everything else at the weekend and evenings. “I ensured the airtightness was monitored and managed daily,” says Gordon. The house achieved 0.35 m³/hr/m² @ 50 Pa, which is significantly better than Passivhaus requirements.

The plant room contains the hot water cylinder with an integrated heat pump

Renewable tech was key to this sustainable project. The couple installed a 4.2kW solar PV array, a Give-Energy 8.2kWh battery store, a Zehnder (Passivhaus-certified) MVHR system and hot water cylinder with integrated heat pump. They chose Passivhaus-certified Viking windows and Velux rooflights, with five layers of glazing and automatic opening purge ventilation in the summer. The house also benefits from 2kW of electric infrared ceiling heaters, but the couple say they are hardly ever used.

“Katie was really keen to have a stove, which we prefer to use for an hour or two on the very coldest of winter days. The heat spreads throughout the house thanks to the open-plan layout,” says Gordon. “A stove is perhaps not ideal for a design aiming for Passivhaus, but we found a small Danish manufactured product with the correct airtightness properties. We can only burn one log at a time or the building begins to overheat.” They find that the house is performing extremely well. Their total monthly heating and energy cost is less than the family’s fibre broadband bill.

Gordon’s brother Andrew, who is a joiner, helped with all the finishing joinery, including the kitchen and oak flooring

Internally, a few changes were made to Gordon’s original layout design on the advice of Es Tresidder, the couple’s Passivhaus consultant. “We moved the stairs to create more flow area and introduced the upper-level bridge,” says Gordon. “Previously, there was a double-height open-plan space, and we were going to add the fourth bedroom at a later stage, but Es’s calculations showed the more floor area you have, the easier it is to comply with the standards. All these things were little incremental changes to help meet Passivhaus standard.” Now they’ve finished the project, designed and modelled in PHPP to achieve Passivhaus compliance, they look forward to gaining certification soon.

All hands on deck

Gordon did all the tiling, with Katie painting and decorating. “I naively thought there might be money left for this, but I had to crack on with it myself,” she says. “There was time pressure as we were renting and I wanted to get into our new house as soon as we could. I had Fridays off work, so would drop the kids off at school and pick them up after school covered in paint. I would also get up really early at the weekends to get a few hours’ work done before everyone got up. I did that from January until October. It was hard going in a four-bedroom house with high ceilings!”

The house has been future-proofed as the ground floor features the master ensuite bedroom. This means all accommodation could be over one level should the owners develop any future mobility issues

Gordon’s brother Andrew Aitken did all the finishing joinery, including the kitchen, doors, skirtings, architraves and oak flooring. The couple’s sons James and Thomas also helped. “The boys got stuck in helping to clear up the site,” says Katie. “We’re working on the barn now and they’ve been helping with that too.”

All the hard work has paid off, as the family really enjoy living in their self built eco home. “What I like about this house is that there is no space that we don’t use,” says Katie. “We are very lucky to be living in such a great property, but we have put in a lot of work to get to this point. I feel like I zoned out of normal life to get this done! I’m not sure I want to do it again – but we don’t need to, as this is where we want to settle.”

WE LEARNED

|

Login/register to save Article for later

Login/register to save Article for later