Building with Straw Bales

Building with straw bales has been enjoying a revival in the UK since the mid 90s. In fact, it’s become the darling of the eco building movement.

Not only does it use a waste product that’s otherwise burned in fields, it also provides fantastic levels of insulation and airtightness. What’s more, its high thermal mass means it’s cool in summer and warm in winter.

The bales’ depth and flexibility result in houses that have great charm and character. They also allow for plenty of alcoves or deep window reveals, and even curved walls.

And they’re pretty durable. Examples of straw bale buildings from 1903 still stand in Nebraska.

How does straw bale work?

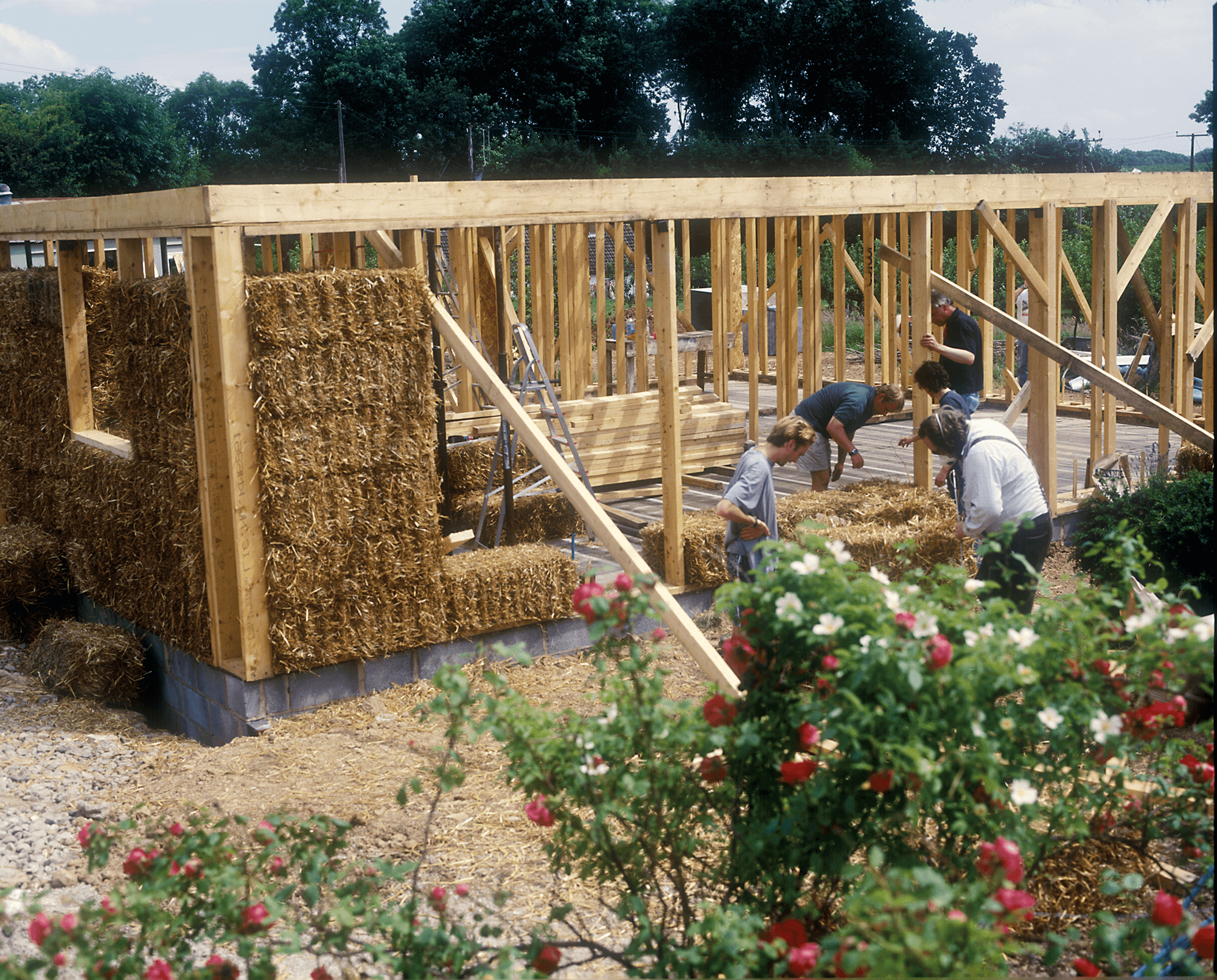

There are two main types of construction: loadbearing and infill. With loadbearing construction bales are stacked like bricks, and take the weight of the floor plate, joists and roof. Doors and windows fit into box frames that are built into the bales as the walls go up.

With the infill method the weight of the roof and floors is carried by a timber, steel or concrete framework. Bales provide the infill and key for plaster. This method allows wider spans and larger openings, but tends to be more expensive.

Either breathable lime or clay render protects the walls of both systems.

Straw Bale House Built for £70,000When Alison and Stuart Sedgwick-Taylor decided to build a small house in their garden back in 2015, they knew building with straw bale was the way forward for them. The resulting design is a circular room that can be easily adapted for varying uses, with two adjoining smaller pods containing the bathroom and kitchen. |

What about fire and pests?

Straw bale houses are no more at risk of fire than those of conventional construction.

The principle is simple. Loose paper burns easily, but you’d have a job setting fire to a telephone directory. Hence, straw compacted in bales is very hard to set fire to as there’s not enough air for combustion. The breathable layer of lime plaster also offers fire protection. Because it is also highly alkaline, it also helps prevent fungal activity.

As for rodents, rats and mice like to have cavities to run around and nest in, so are in fact less likely to be a problem in the solid walls of a straw bale house than a conventional house.

Can I do it myself?

According to Barbara Jones, of straw bale consultancy Amazonails, “it’s ideal for self builders because of its simplicity, accessibility, ease of design and low cost.” If you come unstuck, she runs a mentoring service for self builders and contractors. “A self builder may get an electrician in, for example, who won’t understand how to affix the backplate to the wall as it’s non-standard,” says Barbara. “He can phone us, and we can talk him through.”

Laying building foundations

As straw bale buildings weigh less than masonry, their foundations can be shallower. They should be porous, for example of compacted stone or gabions, to allow any moisture from the building above to drain away, but with a capillary break to prevent moisture wicking up into the walls.

An insulated baseplate is fixed above the foundations if you’re using strip foundations – a structural box beam is used, if piled. Both incorporate pre-drilled cross-pieces to take the hazel stubs on which the straw bales will be impaled (two stubs per bale, positioned evenly along the bale, to just below the height of a bale). Make provision for tie-down and compression straps, too.

Straw bale walls

Straw bale walls need to start 225-450mm from the ground. They must be protected from damp from the outside and in. The bales are laid like bricks, after being trimmed to ensure their edges are square, with the first course impaled on the hazel stubs.

On the fourth course, longer hazel pegs – about three bale-heights in length (less below windows) – are hammered through, two per bale. The peg tops protrude into the floor or roofplate. Hazel staples hold bales together at delicate points, such as above windows or around corners.

Bales can be cut in half and retied, or modified using a chain saw to notch around framing members or allow for electrical boxes, etc. Once the walls are up, hazel stubs are hammered in horizontally to act as fixings for pipes, backplates and cabinets.

When rendering or plastering the bales, always use permeable coatings such as clay or straw-based products. Trim the bales before plastering to provide a smooth surface.

Compressing the walls

The structural strength of the walls really comes when they’re compressed, which also helps make them easier to plaster.

For loadbearing walls, this achieved using ratchet straps that are removed before the roof goes on. With the infill technique, the frame can be designed to compress under the weight of the top beam of the frame. This is then fixed to the floorplate or roof when compression is finished, and infilled with wood.

Windows and doors

Windows and doors can either sit inside structural box frames or be fixed to timber uprights attached to the baseplate and wallplate. According to Barbara: “As there won’t be more than one straw bale above a window or door before the roof or a wallplate, a lintel is not required. Instead, a header of 200mm x 50mm, turned vertically, would support one bale.”

Constructing the roof

Roofs can be of conventional construction, but ensure that the load is carried by the centre of the bales, not the outside edge, and spread as evenly as possibly across the building. Also, ensure you incorporate a generous overhang, of at least 450mm, to protect the walls from rain. Depending on the weight of the roof, you may have to tie it down to the foundations.

Login/register to save Article for later

Login/register to save Article for later

Comments are closed.