House Cladding Guide: How to Use Cladding Materials in Your Home Project

Are you looking for house cladding ideas for your self build, renovation or extension project? It’s wise to think about your cladding choice from the outset of a project to ensure you can fully consider its relation to windows, doors and the size of walls.

Do you want your home’s exterior to stand out or become an architectural feature? Or does the house need to blend into the landscape? The geographical location is vital as not all materials will be suitable. Less durable house cladding options will not work in waterside or coastal locations, while areas with high sun exposure could impact the cladding material’s appearance over time.

Brick, stone and composite options are the easiest to maintain, but if you embrace the natural patina of timber and metal cladding, these can be low-effort options, too. “Cladding simplicity dictates maintenance,” says Teoman Ayas, director of MIM Studios. “Monolithic types, such as rendered blockwork or exposed brick, require low upkeep, whereas metal cladding with many joints, fixtures and crevasses demands more attention.”

Key Considerations for Choosing Your House Cladding

Alongside look at aesthetic, there are a few key questions to ask yourself and your architect when choosing which house cladding could be right for your project’s exterior.

How will your cladding be attached to your property? “Anything fixed will require the building is strong enough to support the weight of what you are putting on it,” says Julie-Ann Clements, director of InEx Design. Face fixing will result in being able to see the nails or attachments, while secret fix methods are more discreet but usually more expensive. “Also think about the lifespan of your product, the work involved to replace it and whether it can be recycled.”

Weigh up your budget with your designer early, too. It may be that more cost-effective options can be used in larger quantities, with some higher-spend materials forming valuable accents within the design. “Rendering over brickwork is a very cost-effective option,” says Teoman.

“Brick-clad buildings are very common, but for small projects, products like London stock external brickwork is not a cheap option. Metal or timber cladding are next in terms of cost, with Japanese-style charred timber designs at the higher end. Porcelain cladding can be more cost effective for small projects than metal and timber and provides a greater longevity” Natural stone looks beautiful, but can be costly and time-consuming to install.

Learn More: Cladding for Home Renovations: How to Upgrade Your Home’s Exterior

International Timber supplied this Accoya modified timber cladding, which is known for its low shrinkage properties and combines stylishly with light natural stone in this project. The cuts in the timber meticulously align with structural details, such as the sliding door sightlines. Photo:

Of course, your local planning authority’s opinion will have an impact on which house cladding you are able to choose. For renovation projects, while small changes to an exterior facade are generally acceptable, works to drastically alter the appearance of a property may require planning consent.

And, if your property is listed or you live within a conservation area, you’ll be subject to stricter rules. “While permitted development wording suggests material similarity, local municipalities might push for using exactly the same materials and house cladding as the surrounding homes,” says Teoman.

It’s advisable to engage with building control, too, particularly if new cladding is to cover more than 25% of an existing building. “Building Regs state any change to a thermal element could require further improvement offsets elsewhere in the building, for example with insulation upgrades,” explains Julie-Ann. “And don’t forget those all-important fire safety standards.”

Learn More: 23 Home Improvement Projects You Can Do Without Planning Permission

EXPERT VIEW Creative house cladding ideasArchitect Julian Owen takes a look at how you can create an eye-catching exterior with house cladding materialsIf your home needs to be a large simple shape, perhaps due to a limited budget or site constraints, its appearance can be enhanced by varying the surface treatment, breaking down the mass into a smaller scale. Changes in cladding can be used to create contrasts either on a single plane or to pick out different parts of the building. Neutral tones tend to recede whilst colourful surfaces appear more prominent. Darker cladding variations (such as metals or charred timber cladding) feel more solid, and lighter ones look less substantial. These effects, which don’t have to bear any relation to the actual construction, are a useful tool for architects to add more character to a property. Above: Bespoke scalloped blocks cast from red pigmented concrete create a colourful exterior in this narrow side return extension by Office S&M. The design is a contemporary take on details from the front of the Victorian terrace house. Floor-to-ceiling glazing and two glazed doors bring light inside, aided by rooflights over the side return. Photo: Megan Taylor A large, flat facade that might otherwise be a little plain can be broken up by changing the surface and splitting it into separate sections. You might do this if you want to create a particular effect. For example, using different cladding on the first floor will emphasise the horizontal nature of a wall. This works especially well if the house is in an open landscape, and you wish to bed it down into its surroundings. If there’s a risk of a building becoming too dominant or being out of scale with its neighbours, a common trick up the architect’s sleeve is to use a light-coloured house cladding material for the upper floors and roof, which reduce their apparent and make it seem less bulky. If a wall is at risk of appearing too wide and uninteresting, it can be broken up with vertical panels. This is harder to get right than a horizontal separation because getting the sizes and proportions right for each panel must be judged by eye. They must integrate neatly with the sizes and locations of the glazing and door openings. Therefore, it’s essential that the plan and elevations are designed together to get the best effect. More from Julian: How to Choose the Right Architect for Your Self Build or Extension Project |

Which Type of House Cladding Material is Best for Your Project?

There’s many different types of cladding available, each with their pros and cons. Your decision will depend on a host of factors, from location to planning stipulations.

Here are the pros and cons of the the main cladding options:

Timber Cladding

Timber cladding can create a range of exciting exterior looks. This can run from vertical or horizontal arrangements, through to shiplap, slatted, scalloped-edge designs and statement shingles, plus interesting patterns and the increasingly desirable style of Shou Sugi Ban, the Japanese art of charring wood for a sleek, blackened effect.

Weathered Siberian larch cladding makes a statement in this project, designed by Millar + Howard Workshop. To add interest, cladding boards of different sizes and laying patterns were used, and a slatted larch screen was installed over the upstairs bathroom window for privacy. Photo: Charlotte Ferrier

Combining timber species like larch or cedar with another natural material, such as brick or stone, can add visual interest, while pairing it with a metal, such as zinc, offers a more industrial look. “Consider the direction of the timber cladding. Horizontal designs need a single vertical batten, whereas vertical cladding will require an additional counter batten at extra cost,” explains Julie-Ann.

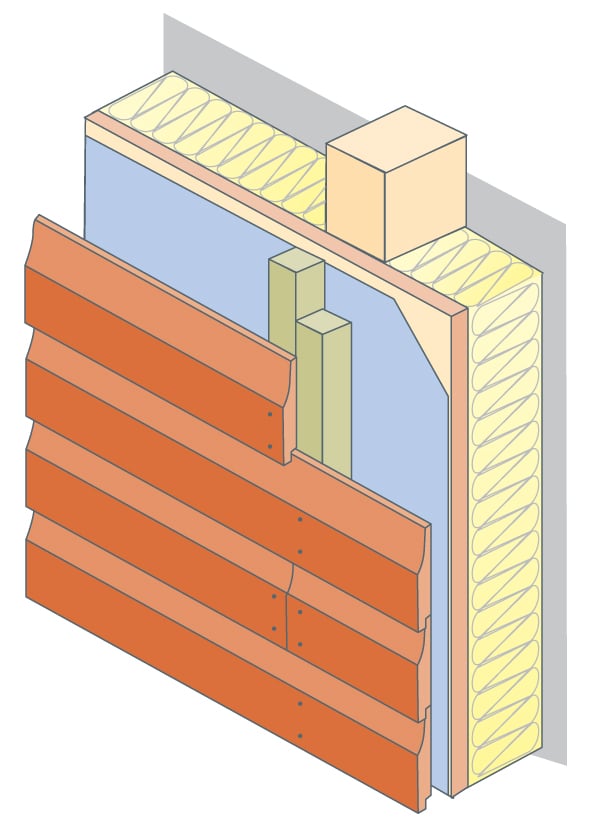

CLOSER LOOK Installing timber claddingWhen attaching horizontal timber house cladding, a standard detail is to use a single layer of vertical battens to achieve the required airgap, but Simon Orrells from timber frame supplier, Frame Technologies, advises even greater prudence. “Best practice is to double-batten to be certain you’re going to get enough cross-flow ventilation,” he says. “If you only use a single batten and the airflow gets blocked somehow – for instance at the bottom of the cladding – then you’ll get stale air in the cavity.”

Wherever you’re using a horizontal batten, this should be chamfered so that the water is directed away from the structural fabric (ie back towards the cladding in the case of a single batten, or into the centre of the cavity if you’re using cross-battening). Around windows and doors, special trims will be needed, and potentially an insect mesh (also known as a perforated closure). |

No matter the timber cladding’s laying pattern, weathering is the most important consideration. “Timber is a natural material, which will weather over time to a silver-grey colour,” says Fraser Hourston, architectural liaison technician at Russwood. “This process takes around two years in a well exposed location, depending on the timber’s species. Uneven weathering can be caused by differing exposure levels.”

Coating your timber with a wood protection system such as SiOO:X, which accelerates the weathering process, will result in a more even look. Uncoated timber will naturally weather and can last decades without maintenance, as long as it’s durable and installed correctly.

More Ideas: Timber Cladding Design Ideas for Your Self Build Project

Charred timber cladding marries with steel-framed doors to set this extension apart from the existing building. A similar extension would start at £86,000 from Plus Rooms

Modified timbers, such as Abodo, Accoya and Thermopine, will have a notably higher durability class. “Your house cladding should be inspected annually to catch any potential issues before they develop further. A wash with soapy water can be beneficial, especially if your home is located in a wooded area and vegetation spores can land on the cladding,” says Fraser. From an environmental perspective, always seek out the timber’s origin to make sure it’s from sustainable sources – look for FSC or PEFC certification.

QUICK GUIDE House cladding ideas for mixing & matching materials

|

Metal Cladding

Steel, aluminium, zinc and copper can add contemporary accents to a home’s exterior. Weatherproof, hardwearing and low maintenance, metal options can be coated or uncoated, and they often have a long lifespan. House cladding materials such as zinc and copper will develop a patina over time if left untreated.

This type of house cladding offers a great range of finishes and effects. “Most metal cladding is relatively light and, if you can securely fix a rail system to the building, this can be a good choice. Rails can be – to a point – as deep as you want, so they can hide an existing building to great effect,” says Julie-Ann. “You could even have two cladding systems stacked over each other, for example, maybe the outer one moves to help with security or keep the sun out.”

Anthra-zinc Plus standing seam roofing and cladding, from VMZinc, costs around £150-200 per m² including flashings but not rainwater systems or the substrate

Metals such as zinc can look great with many other house cladding materials – including slate, stone, brickwork and timber – and can also be used for roofs. When combining metal with timber, it’s usually positioned above wood cladding, otherwise water run off carrying timber extractives can stain the metal. That said, some metals can stain timber – seek advice from specialist installers for best results.

CLOSER LOOK Combining your house cladding with other featuresThink about how your house cladding, doors and windows will work together. Are you framing a view with your glazing? Do you want the window to project outside the building line? Maybe you’d like the frames to line through with your cladding. Perhaps you want to inlay the cladding inside some of the fenestration? Whatever window system you’re using, it needs to be properly planned into the cladding design. “Getting this interface correct begins at the design stage,” says Rebecca Clayton, director at IQ Glass. “The technical detailing by the architectural glazier should be done in conjunction with the architect or principal designer, to ensure that the connection or meeting between the cladding and glazing has been fully thought through. You want to ensure that any connections are neat and you may also want to look at aligning any joints in the cladding with corners or elements of the glazing.”

The right selection of doors and windows can really add something to the final design. Frames can be specified in any RAL colour and while slim frames are popular to capture views, thicker options can provide aesthetic appeal to enhance a build’s architecture. “A high-contrast frame colour against the house cladding can highlight fenestration, while a similar colour can help blend them in,” says Teoman Ayas, director at MIM Studios. “Specific window systems that literally pop out (such as oriel windows), versions that sink in with deep sills, or those with protruding metal perimeter trims, can all add playfulness to the overall facade.” |

Exterior Brick Finishes

Bricks don’t have to be laid in the common running bond format, and new options such as brick slips offer the opportunity to for extra wow on new or existing homes. They are a great, cost-effective house cladding option.

“Brick slips are essentially tiles as opposed to structural bricks, so you can use them in any pattern you like, from traditional stretcher bond to Flemish or English bond – using half tiles cut from the ends of the brick – or herringbone, basketweave, or just randomly placed half tiles. You really can do whatever look you’d like,” says Joe Burton, brand director at The Brick Tile Company. “Using brick slips as cladding means you can make different and more intricate design choices as the mortar isn’t functional, it’s aesthetic.”

More Inspiration: Brick Design Ideas: 20 Amazing Ways to Use Masonry in Your Project

The exterior of this Victorian semi-detached property was clad in glazed brick slips in a Midnight colourway. The whole house refit, including an infill extension and ground floor reconfiguration, was designed by Fraher & Findlay and was undertaken on a budget of £4,000 per m². Photo: Chris Wharton

Installing brick slips takes around 30 minutes per m² on average, according to Joe, but this would increase with less uniform brick slips, patterns or reclaimed brick styles.

If you’re going for an intricate pattern, you may be best enlisting a tiler, but a bricklayer or general tradesperson will also be able to install it for you. Of course, there are plenty of options for traditional brick, too – including sleek contemporary units and characterful handmade bricks.

Tile Cladding

Ceramic or porcelain cladding materials are extremely versatile, impermeable and very durable, plus there are a wide range of styles, colours, patterns and textures on offer so you can choose an option that suits your project. These materials can be used in super-modern settings to great effect, or to recreate the look of traditional hewn stone.

Panelled porcelain cladding offers efficient coverage of large areas and can replicate vertical panelling. Smaller tiles, such as metro-style designs, can also be used for a more intricate design.

The weight of the house cladding material is a key factor and checks must be made to ensure the existing home’s surface is suitable. The substructure must be strong enough to bear the weight. If this type of cladding is to be higher than ground-floor level, mechanical fixing is recommended.

PVCu Cladding

Modern manufacturing techniques mean plastic cladding is now a real option for homeowners, particularly those looking to update a tired facade. It comes in a wide range of finishes and hues, with all the low-maintenance qualities you’d expect of PVCu, and at a affordable price point.

This PVCu shiplap cladding from Swish Building Products features a foiled finish to replicate the look of wood

As with any product, watch out for low-quality versions. These are likely to be susceptible to issues such as fading, warping and cracking over time – especially in exposed locations. The best examples should offer a service life of three decades or more.

Cladding Your Home with Render

Render is applied in layers, by hand in a similar way to internal plaster, or by spraying, and can easily be given a textured or patterned finish.

Many self builders and renovators now choose modern render systems, such as silicone render. These are thinner and quicker to apply, as well as being through-coloured. This makes products such as silicone render a low-maintenance option.

Read More: Complete Guide to Render Options and Costs

Baufritz designed this Bauhaus-inspired self build for downsizers who wanted a home that would see them through into old age. The modern, mineral-based render is factory-applied in Germany during prefabrication of the timber frame house shell

Rendering might seem like an approachable job, but it’s much harder to get right than it seems. So, if you’re after a smooth finish, it’s always best to call in the professionals. That’s especially true of modern render systems.

External wall insulation covered by a render of your choice can be applied to new or existing homes to improve warmth and comfort levels. Specialist thermal renders are also available. Application takes around three days. Find an installer at the Insulated Render & Cladding Association.

This article was originally published in August 2020 and has been republished in April 2024. Words by Lindsay Blair & Caroline Rodrigues.

Login/register to save Article for later

Login/register to save Article for later

The battens are typically attached at 600mm centres, although this may be altered depending on the location of your project (ie how exposed the site or elevation is to wind and rain) and the exact material used. Green oak cladding, for instance, is likely to move a lot – so the battens might be positioned closer together to minimise this. Timber and wood-effect claddings are usually nailed or screwed using corrosion-resistant galvanised or stainless steel fixings.

The battens are typically attached at 600mm centres, although this may be altered depending on the location of your project (ie how exposed the site or elevation is to wind and rain) and the exact material used. Green oak cladding, for instance, is likely to move a lot – so the battens might be positioned closer together to minimise this. Timber and wood-effect claddings are usually nailed or screwed using corrosion-resistant galvanised or stainless steel fixings.

Comments are closed.