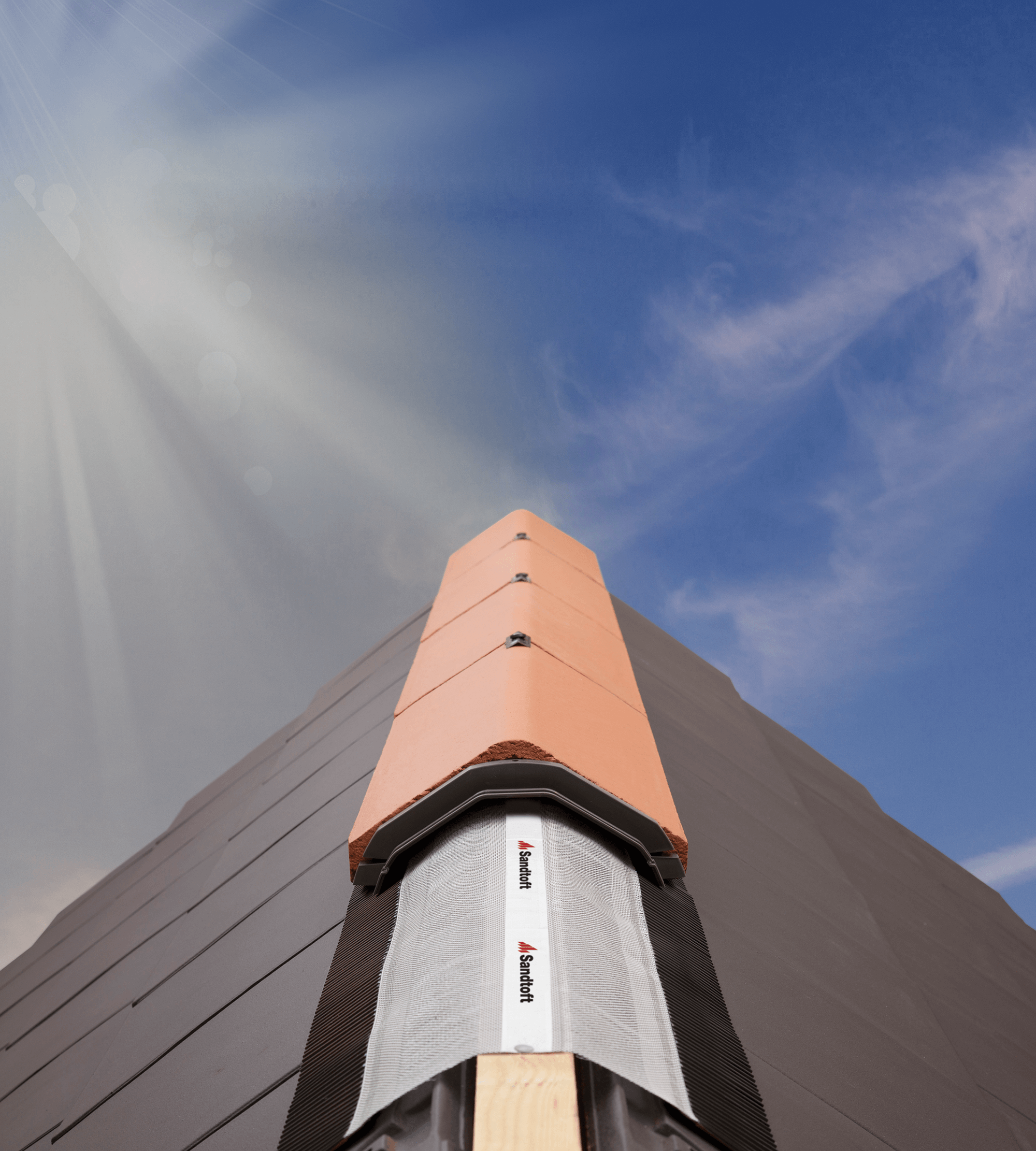

Dry Ridge Tiles

Installed as part of a mechanical-fix roofing system, dry ridge tiles are designed to be used at the apex of a roof covering and are fitted without using mortar. It’s becoming the method of choice in the construction industry as it offers a low maintenance solution lasting up to 30 years.

Why use this system?

Conventionally, ridge tiles have been secured using mortar (a mixture of cement, sand and water) to glue the units together. However, this method is increasingly falling out of favour because it is highly susceptible to moisture ingress, which is difficult to avoid given the UK’s wet weather conditions.

In addition, mortar is an inflexible material that can crack as homes move and settle. It will eventually fail, and as a result tiles can become displaced or water can enter through the gaps in the seal, potentially causing damp issues.

The traditional route leads to even more problems should the installer incorrectly use a weak mortar mix. Combine this risk with the possibility of rainfall during the job, and the result could be that the mortar degrades a lot quicker than it should do.

Applying a mechanical fix allows you to eliminate the use of mortar and avoid continual maintenance or cracking. What’s more, as UK homes are now better-sealed and insulated, the need for improved ventilation becomes more pressing.

Without a route of escape warm, moisture-laden air in roof spaces can lead to serious condensation and mould issues. Dry fix systems provide an opportunity to install a ventilated solution that negates much of this risk.

There are a number of other benefits. For instance, dry ridge tiles are easy to install. Once the main roof tiles have been fitted, a membrane or underlay is rolled over the apex. The individual ridge tiles, starting with the end unit, are then secured using a special connector (known as a union) between each piece. This union replaces the mortar and is fixed in place using a screw, clip or plate as specified by the manufacturer.

What to consider

A mechanical fix is not typically considered to be suitable for the refurbishment of heritage properties, where planning or listed building restrictions may require you to achieve an authentic aesthetic.

To make sure that there are no compatibility issues, it’s best to source the complete roofing system from the same company. If you’re mixing products from different manufacturers or using a version not specifically designed for your roof type, then you can encounter problems. This is most likely to occur with unusually-shaped, steeply-pitched or flat coverings – so be sure to get advice from the supplier.

Sandtoft makes a dry fix solution that’s compatible with its own brand tile range. The company’s Universal works with a variety of profiles, including half round, leg angle ridge and segmental ridge. Marley Eternit’s Universal Ridge Fast is a ventilated fibre cement system. It can be paired with its slate and clay units on roofs of up to 55° pitch to offer a weathertight and maintenance free finish.

Cost

These days, most roofers will offer their customers the same installed price for both dry-fit and mortar-based ridge systems. This is because the speed at which dry types can be fitted makes up for the slight difference in materials costs.

Dry-ridge packs are sold according to the size of the roll-out membrane, which is commonly available in 3m, 6m and 10m lengths. Prices start from around £25 for a 3m kit including the roll, seals, screws etc – but you’ll need to purchase the ridge tiles separately to suit your roof style.

Login/register to save Article for later

Login/register to save Article for later

Comments are closed.