Use code BUILD for 20% off

Book here!

Use code BUILD for 20% off

Book here!The name is a mix of the English and French terms for cob which is a natural building material that has been used since prehistoric times on both sides of the Channel. It’s particularly prevalent in the South West of the UK. We’ve looked into these conventional techniques to create a strong construction material.

Learn more: Building with Cob

English cob is traditionally a mix of soil, straw and water. It works very well for walls – rooms are warm in winter and cool in summer – but by using the material in its pure form, it isn’t easy to create a structure that complies with modern Building Regulations. We’ve been researching how to keep the method’s efficiency while also meeting today’s standards.

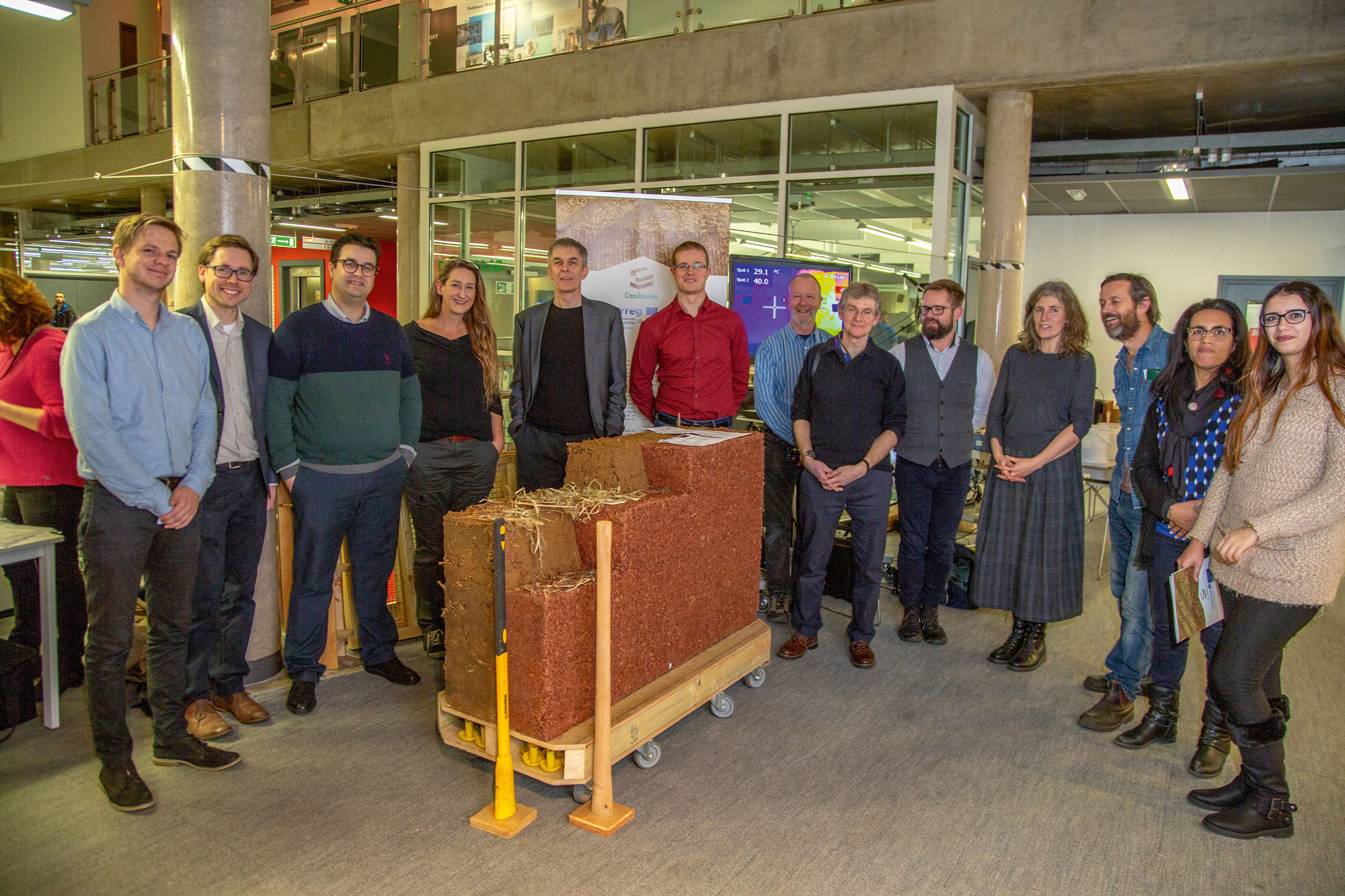

The CobBauge team have been researching the best ways to create this building material

Our work has been a collaboration with a team in France to combine traditional cob building from both countries. The project aim is to create and monitor two pilot properties made from the result of our research, a material we’ve called CobBauge. We’ll be looking at energy consumption, thermal comfort and indoor air quality and compare it to other buildings. We believe the product is fantastic, but others will need to see it in action.

We started by looking into what materials would work best to make the product. That collaborative approach gives us an edge, as we had access to techniques and materials both here and in France. For example, we’re using reeds, which are normally waste products from the cob-making process in France. They don’t really come into it here so would have otherwise passed us by.

It’s fantastic to have the findings from both sides of the Channel agree in terms of the best mixture of materials to provide strength, thermal comfort and efficiency. This sharing of resources and results is like our own internal peer review and strengthens our findings that CobBauge is a viable material. Our next step is to create small prototype buildings – these are in addition to the occupied pilot properties still being planned.

Having people live in the pilot buildings is critical. We could try simulated occupation, with various heaters and devices to humidify the air, but there’s nothing quite like having people, because they do the unexpected. This is where the team at Hudson Architects come in. They’re going to design a fantastic home that uses CobBauge for a client who wants to try an innovative product, but with a long historical lineage behind it.

It’s a thermally efficient material, with built-in insulation and very low embodied energy values. You can be reassured that the property you’re putting up has consumed and is only going to use a small amount of energy. There’s also very little waste.

You can reuse the material at the end of its lifecycle, and there doesn’t seem to be any loss of properties when you break it down and remake it. But if you really want to get rid of the stuff, it’s just subsoil and natural fibre, so it won’t damage the environment. We love that cob also fits in with historical cultural identity throughout the country – many highly energy-efficient building techniques don’t because they’ve not been around very long.

There are some limitations though. If you’re constructing a three-storey cob building, the walls tend to get quite thick. At the moment, it’s more logical to limit it to two-level properties. However, further research might help us find a solution to that.

Speak with your local authority about the material – they can be restrictive in either the technologies used for a new build, or in the overall design. We’ve come across some people who are interested in using CobBauge for their building projects, but the conditions imposed by their council mean that they don’t have the freedom to use this form of building.

If you’re interested in the practicalities of materials going into your home, or you even want to do a lot of the work yourself, then coming to events and experiencing them first-hand is important.

Our prototype buildings – in Plymouth and in Normandy – will provide the opportunity for people to actually get their hands dirty by helping to build the structures. We need to train the tradespeople to use this material, so that can include self builders.

As the CobBauge project runs through to the next phase and the construction of the pilot buildings, we’ll be holding more training events. I’d also encourage anyone interested in this material to link up with Earth Building UK and Ireland (EBUKI).

Find out more about the project

Contact Hudson Architects