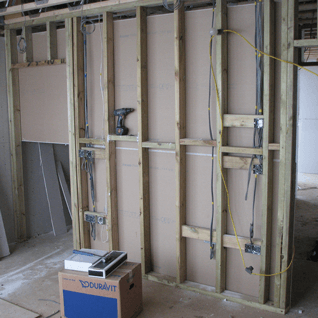

We have been moving ahead with the first fix. It’s not very photogenic, but hanging wires and loopy plastic pipes seem very exciting to us.

We’ve been endlessly making impossible decisions about the positions of thermostats, light switches, uplighters and such like.

Unfortunately, the first fix is taking a lot longer than had been expected. The electricians took over three weeks to finish, rather than the one and a half on the schedule. Also, the electrical work has turned out to be a lot more expensive than the provisional estimate in the contract, which has been a pain.

I wasn’t desperately happy about the sudden arrival of £10,000 of unexpected cost, which we have had to work hard to reduce. The design was over complicated; the provisional figure in the contract would have probably given us a light bulb in each room.

There are a couple of other provisional large item figures, for tiling and oak floors, which we have checked and which seem more realistic. It has been a valuable lesson – although sometimes I’m not sure whether it’s a good or a bad thing to be on site. Being so easily accessible means I’m asked to make numerous on the spot decisions.

Anyway, the electricians working on the revised design – Mainstones – have been very good, and worked hard. They’re from just around the corner in Bruton, which is going to be helpful in the future.

We’ve also had the alarm people in and have fitted a meter in the garage, which now has a concrete floor.

The other internal work has started, too, such as plasterboarding the top box. We can’t push forward with it as quickly as we’d like as the heat recovery system hasn’t arrived yet. This piece of kit will whizz air around the house, via ducting in the ceiling, to a central recovery unit.

It not only equalizes temperature and reduces humidity in wetter areas, but also brings fresh air into the house (which it heats up using the warmth recovered from stale air). The ducting design is deliberately wiggly so that sound doesn’t travel along it, and will be fireproofed.

However, the company providing it were slow with the drawings, and then the fitter didn’t arrive when he said he was going to. Without getting the ducts in, we can’t plaster the ceilings. This sort of thing is enormously frustrating.

The bathroom fittings are all on site, arriving with boxes stuffed full of plumbing exotica. I’m sure it will all make sense at some point. The plumber has also been working hard on his first fix and seems to be getting the hang of it.

We’ve built the hopper for the wood pellet boiler and drilled some great big holes for it through a wall outside the thermal envelope.

Login/register to save Article for later

Login/register to save Article for later