How to Get the Best out of Building with SIPs

Despite their popularity in Scandinavia and the fact they offer a number of benefits for home building projects, structural insulated panels (SIPs) have only recently been established as a mainstream option in the UK.

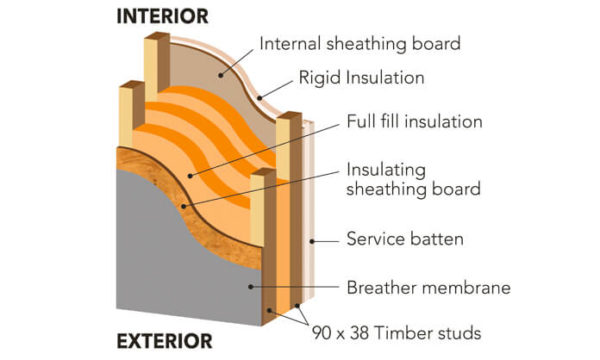

The system comprises pre-insulated panels, usually made from engineered wood-based sheets sandwiched together with a core of high quality rigid insulation – like polyurethane – in between.

A strong, lightweight system, SIPs can be manufactured to create large sections of wall, floor and roof, and are typically supplied in kit form to make a whole house.

“It’s a strange thing to say, but homes constructed with SIPs have a very solid quality to them, because you’re reducing the number of elements needed for a build,” says Malcolm Thomson, managing director of SIPs Scotland. “It makes a big difference to the overall feel of the property.”

Read more: Build Your Home Fast and Cheaper with SIPs

The panels are made in a factory to your own bespoke requirements and then slotted together on site. Some prefab specialists can even supply them with windows and doors, plasterboard lining and service channels already installed.

This means that once the SIPs kit is delivered, the shell of your new home can be erected far quicker than with a traditional construction method. So, if you’ve made the choice to go down this route for your project, read on to find out how to make the most of this innovative system.

SIPs offer superb energy efficiency performance

SIPs are renowned for offering exceptional thermal performance, which can significantly exceed Building Regulations without the need for excessively thick walls.

“They give you a very simple way to build to Passivhaus principles,” says Andy Porter, partner at SIPS@Clays. “You get a really well insulated property without making any extra effort, as there aren’t any gaps in the joins like you can sometimes find with other methods.”

While you can opt to install the panels on just the walls or the roof, for the best energy efficiency, Malcolm and Andy both recommend using a complete package.

“It depends on the desired performance that you’re trying to achieve,” says Malcolm, “but you’ll hit higher targets more easily with a full kit.”

This contemporary home by SIPs Scotland features a traditional stone exterior topped with a sloping roof. The property was built with Kingspan TEK panels

That’s because working with a single system and supplier means the structural design, supply and erection is all done under one roof – giving you confidence the planned performance will be achieved.

It can also help with budgeting and project scheduling. “Because the panels are pre-insulated, once you’re on site and the house has been erected, the insulation is automatically done,” Malcolm continues. “With some other systems you have to go back and add in several extra layers. That takes a lot of time and labour and therefore can increase the subsequent costs.”

| EXPERT VIEW Maximising the Speed Benefits of SIPs Construction

Potton’s Mark Stevenson gives his top tips on how SIPs can boost build speeds and get you in your new home quicker: Getting your build ‘in the dry’, also known as reaching weathertight stage, is an important milestone for every self builder. As an offsite construction method, SIPs are the perfect solution for a speedy build. The SIP panels are part-assembled in a factory and then transported to site, where assembly is completed. This allows for rapid erection times. In fact, the superstructure of a SIPs house can be fully erected and weathertight within two to three weeks, depending on the architectural complexity. This rapid build time allows for your internal works to begin sooner. So, whilst the cladding is still being fitted externally, trades inside your house can get to work simultaneously. Using SIPs also reduces costs for labour, project management, and scaffolding, and improves site health and safety. Reaching weathertight stage on your project so quickly also delivers you to a critical funding milestone if you’re using a self build mortgage. This allows funds to be released sooner and will accelerate the following stages of your dream home building project. Mark Stevenson has been a construction professional for almost 30 years. He became managing director of Potton after an extensive career in housebuilding, and now helps self builders create their own homes. Potton is a Structural Timber Association STA Assure Gold Member. |

Design possibilities for SIPs builds

When it comes to planning your SIPs home, arguably, the only potential limitation is your own imagination.

Houses of all sizes and shapes are possible, and after the structure is complete, it can be clad with pretty much anything you like. So, whether you want a traditional build with a classical stone finish or a modern white rendered abode featuring large swathes of glass, it is all very much achievable.

One design element that SIPs do lend themselves especially well to is creating spacious living areas in lofts, thanks to their strength and insulation performance in a relatively lean panel thickness.

“If you have paid good money for a plot of land, why would you put roof trusses in?” asks Andy. “You might be looking at what would traditionally be a two-storey residence with a standard covering, but using a SIPs system, you could achieve three full levels with a nice, versatile room in the attic.”

But while the sky is the limit when it comes to aesthetics, as with any build, you must hire the right professionals if you’re keen to get the best out of your scheme.

SIPS@Clays built this large, modern Northumberland home, which is clad in attractive grey bricks and features lots of fenestration

“Having a good architect with a strong knowledge of the system will assist in maximising the overall benefits,” says Malcolm. “They can help you with factors like window placement for solar gain and adding to the house’s overall performance.”

In terms of the SIPs structure itself, working with an experienced designer can help identify cost efficiencies. For instance, the most economical roof form will be to combine the panels with a ridge beam and apex gable ends.

“From a practical point of view, this is the most efficient way to build the kit,” Malcolm continues. “It’s very simple engineering-wise, which keeps fees low.”

As a result of the excellent levels of airtightness that are inherent with a SIPs build, you need to ensure that you’ve got a good stream of fresh air circulating throughout the house via proper ventilation.

“This is the same as it would be in any highly efficient property,” says Malcolm. He recommends installing a mechanical ventilation heat recovery (MVHR) system to maintain a fresh air supply.

Value for money

Costs are typically slightly higher than conventional timber frame, but you benefit from simplicity in terms of airtightness detailing and on-site quality control.

“For a well-finished house, built with high quality materials and fully-managed and erected by a professional, I’d estimate from £1,800 to £2,000 per m2,” says John Langley, director of JML SIPs.

Maximise glazing in your SIPs home

Opting for a high-performance setup such as SIPs can help to enable greater use of glass in your scheme.

The panels, the insulation and airtightness values can offset the comparatively lower U-values of windows, feature glazing and sliding doors.

Their strength and performance also means these panels can also be used to create wow-factor features like impressive vaulted ceilings.

There are limits to how far the SIPs can span without extra supports, of course, but your structural supplier can advise.

Learn more: How to Specify Glazing for your Project

Should you decide to opt for a style with a lot of glass, Andy suggests adding more internal insulation to avoid any potential issues with cold bridges – especially if you’re aiming for Passivhaus or a similar standard.

“It’s a common sense approach that’s being more frequently implemented in the self build projects we see,” he says.

Historic Home Transformed by Modern SIPs Extension

Having lived in London for seven years, Caroline and Gustavo Ordonez-Sanz came to the point where they yearned for a quieter lifestyle. They decided upon Stirling in Scotland, where Caroline grew up, purchasing a handsome Victorian period property. The C listed property was built circa 1870 and was in need of modernisation, but the couple was keen to undertake an extension project, too. Using SIPs, as well as ample glass, zinc and wood to complement the home’s sandstone façade, Caroline and Gustavo created a gorgeous contemporary addition that enhances their historic home. |

Attention to detail is vital here. “Many new houses are built with lots of glazing and the lintel heads around them can be quite substantial,” Andy continues.

“As there’s no insulation there, it becomes a weak point in your thermal envelope.” Adding 25 to 30mm of internal insulation to a standard 142mm panel can remove an element of

that cold bridge – allowing you to enjoy the aesthetics of contemporary design without increasing your heating bill.

Mix & match SIPs with other construction systems

One of the advantages of this system is that it can partner well with other construction methods. You could build in blockwork or insulating concrete formwork (ICF) for the walling, for instance, and top the house with SIPs to create a live-in loft.

The panels are also often used as an insulating wrap for oak frame builds. “You can keep the structural beams visible inside the house as a feature and wrap the SIPs around them externally,” says Malcolm.

“This gives you the energy efficiency of the structural insulated panels with the beautiful aesthetics of the oak internally.”

However, if you’re building to a strict time frame or want to minimise potential disconnects in the process, you might consider sticking to a singular system for all of the structural elements.

“Once multiple suppliers and trades start getting involved, there is a crossover of responsibility and accuracy,” says Andy.

“We often get asked to put our panels on the roof of a traditional construction. While this is perfectly doable, that house needs to have been built really precisely. SIPs are made to within 2mm of accuracy, so if measurements aren’t exactly right, it becomes tricky to determine who’s going to ensure everything fits together.”

Top image: SIPS@Clays created this sprawling modern build, which fully demonstrates the design potential of SIPs panels with its variety of jutting lines and angles

Find structural systems in Build It’s directoryAt the heart of any major self build or renovation project is the structural system you choose. Find specialist suppliers for brick-and-block, timber frame, structural insulated panels (SIPs), insulating concrete formwork (ICF) and alternative construction methods. |

Login/register to save Article for later

Login/register to save Article for later