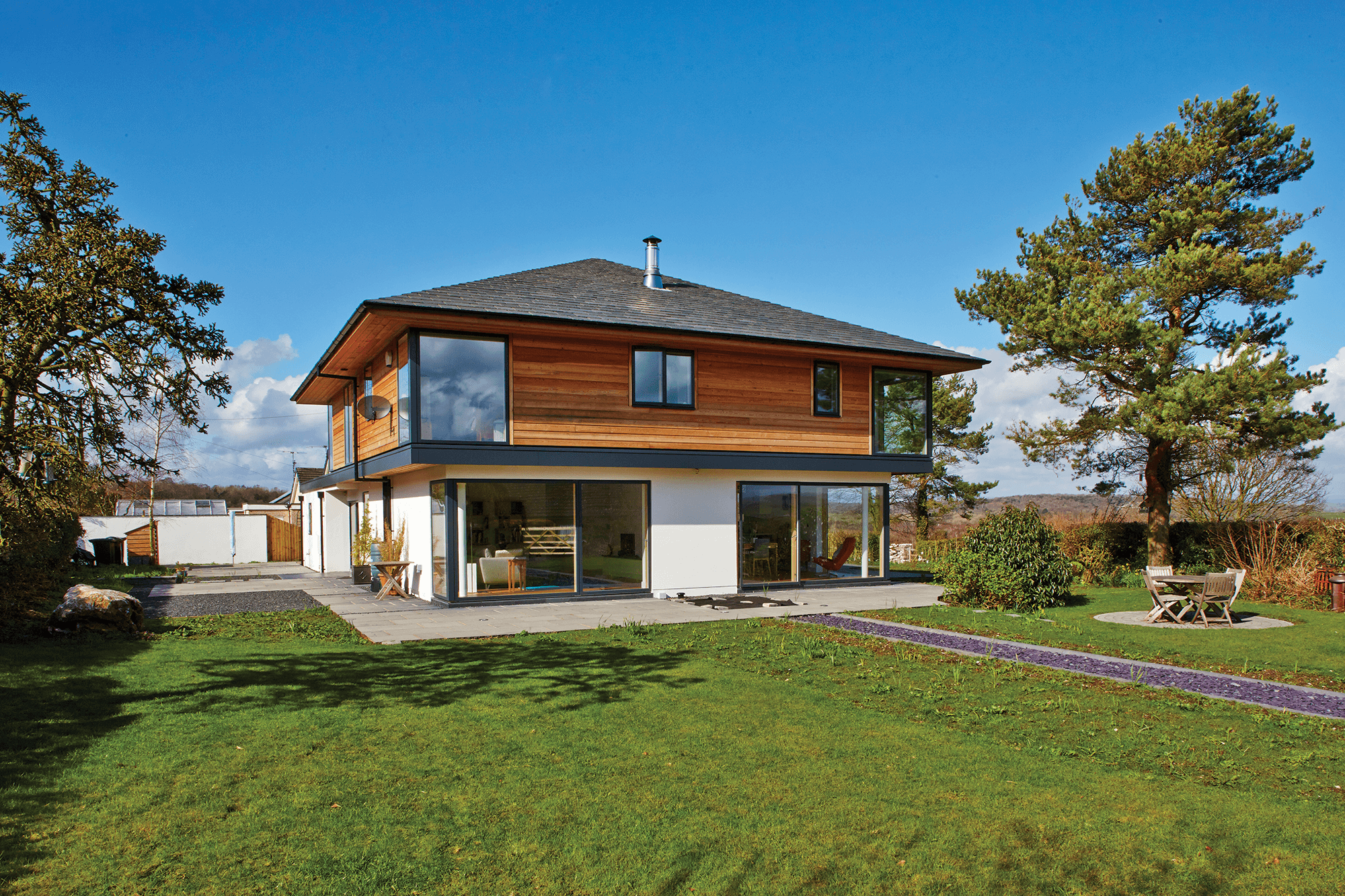

Modern Self-Build Home with Larch-Clad Cantilever

This larch-clad property, with its clean white render, low-lying roof and defined geometric lines, evokes style elements seen in Scandinavian or Japanese houses – but in fact, it’s closer to home, on the edge of the Lake District.

Unsurprisingly, Elspeth Jones and her partner Fiona Inglis were delighted when they first saw the plans – even though they’d had no input into the design. “The contemporary style was stunning and planning was already in place. We couldn’t believe we had permission to build this sort of house straight away,” says Elspeth.

Finding a plot to self-build

The couple found themselves in this fortunate situation after discovering the site in early 2012. Elspeth had thrown her heart and soul into looking for a plot near to where they lived, as land was scarce and they were desperate to self-build.

“I sent letters to architects and contractors in the area and we struck lucky one day when a builder we know contacted his friend, who was considering selling his land with planning permission,” says Elspeth.

The plot was a partly demolished 1950s bungalow on a third of an acre in a Lancashire village; it was at the end of a small row of bungalows with an open aspect across to the Lakeland fells. “It’s a quiet spot with amazing views,” says Elspeth. “It sounds twee but when Fiona and I went to have a look one snowy February morning, it felt like home from the start.”

- NameElspeth Jones & Fiona Inglis

- LocationLancashire

- ProjectSelf-build

- StyleContemporary

- Construction methodTimber frame with steel

- House size267m²

- Plot cost£275,000

- Build cost£367,000

- Build cost per m²£1,375

- Construction time9 months

- Current value£700,000

That May, a figure of £275,000 was agreed upon for the plot. The couple went to see JMP Architects, which had prepared the drawings, and chatted to director Neil Nute and project architect Conrad Till about the design in more detail. Neil and Conrad reminded them they could have a completely different design if they wanted, but the couple were wary about making significant changes.

“We thought it had probably been hard enough to get planning approval for a contemporary house in an area of outstanding natural beauty,” says Elspeth. “If we made extensive alterations we might struggle to get permission again and going through the process would increase our overall expenditure, too.”

Pricing the project

As they looked in more detail at the design, the couple discovered the house was going to cost about £350,000 to build.

“Our budget at the time was only £250,000 so we needed to go away and have a long hard think about whether we could go ahead,” says Elspeth. Before buying the plot they had always imagined they would opt for a more traditional design, but in the end they came to the conclusion that this was an opportunity not to be missed.

“We really embraced JMP’s contemporary drawings and the concept of open plan living,” says Elspeth. “We knew this was our chance to build a unique house, so we decided to take the long view.” The couple managed to raise the extra funds they needed through savings and a self-build mortgage with Furness Building Society.

Although the external design and materials were locked in by the detailed planning approval, Elspeth and Fiona were keen to make changes to the interior elements. They decided to radically alter the upstairs layout by adjusting the bedroom sizes to create a bigger master bedroom with a walk-in wardrobe and ensuite, and to maximise the rural views.

Downstairs they widened the kitchen to accommodate the design they’d worked on with Webbs of Kendal, and encased the dual-aspect stove and flue instead of having it freestanding, to provide a solid divider for the room.

Organisation is key

By now the couple had sold their home and were renting a bungalow nearby. The couple decided to bring in JMP to formally manage the project, with Elspeth – who runs a local cake business – playing an active role. “This decision was more expensive, but Fiona and I felt it may have cost us a whole lot more if there had been a serious mistake because this was our first self-build home,” she says.

Elspeth spent six months working on changes to the design with Conrad, and endless weekends were taken up by shopping with Fiona to make decisions on all the materials, right down to the last plug socket.

“Preparation was the most crucial part of the project because we wanted to build to a fixed price,” says Elspeth. “We gave ourselves plenty of time to choose the bathrooms, kitchen and all the other details so everything was fully costed up and in place before work began on site.”

Conrad sent the project out to tender to six local contractors. Paul Wood from Branstone Beck Development became a favourite, so Elspeth and Fiona went to have a look at his work and liked what they saw. Paul and his team came on board, and in December 2012 the project got underway with the full demolition of the bungalow.

“He was really great to work with and it was good to see he was a real disciplinarian,” says Elspeth. “The team functioned really well together and were also very courteous to our neighbours, who were patient and accommodating throughout.”

Building the house

The shell of this home is constructed from engineered timber frame on the lower and upper levels, with steel beams supporting the cantilevered first floor and roof. The timber frame construction was a slight sticking point for Elspeth, as her family has a 50-year history of concrete block-making through their company, Plasmor. Elspeth’s brother Julian now runs the business, which also manufactures paving.

“It was definitely a controversial decision,” says Elspeth. “But it was still important to use the family firm, so Plasmor’s blocks clad the ground floor walls and were used to construct the floor and garage. We also used their pavers on the driveway.”

At first the architect and builders were hopeful they could construct the house on the bungalow’s old foundations. But once it had been demolished it became apparent that these weren’t adequate. New plastic water pipes were also going to be needed to replace the lead ones.

A run of cold but dry weather during February and March helped the timber frame go up smoothly. When the scaffolding was erected, Elspeth and Fiona were able to see the view at height for the first time. “We hadn’t been able to go upstairs in the dormer bungalow because the interior had been partly demolished, so we had no idea quite how spectacular the surrounding countryside was until this point,” says Elspeth.

Weekly meetings between Elspeth, Paul, Conrad and the other trades kept the project running on time, and nine months later the house was finished. “Building to the original design was really key to the project’s success,” says Elspeth. “I just had to be very disciplined, and not change my mind about anything along the way!”

That said, the couple did make a few changes after the internal walls had been built. “I wanted the staircase to feel light and open so Conrad came back with some alternative ideas and created a brilliant open-riser design” says Elspeth. “It cost an extra £6,000 but I don’t think that was too bad in the grand scheme of things. We just had to make sure whenever we increased our costs we found a saving elsewhere to keep our budget balanced.”

A place to call home

The finished house is a striking property. A strip of grey aluminium flashing creates a demarcation between the upper and lower levels, while larch cladding and a white silicon render highlight the form of the building. Echoes of the slate roof are found in the black limestone paving and even the slate hearth inside. The Velfac window system fits with the house’s contemporary style, with anthracite frames on the outside to match the flashing, and pine interiors.

“Conrad’s really thought about the order and symmetry of the materials and that really appeals to me,” says Elspeth. “I love that the floor-to-ceiling windows are placed in all four corners of the house and follow the sun’s path. Even on darker days the quality of the light is incredible.”

Elspeth says even Paul the builder – who has built close to a hundred properties – is particularly proud of this house. “It’s such a beautiful home to live in and I will never get tired of the views,” she says. “The whole self-build process was fantastic; I’m only just coming back down to earth from the adrenalin rush.”

Login/register to save Article for later

Login/register to save Article for later