Scandinavian-Inspired Timber Frame Home

When Susan and Michael Zappert were looking to retire, they decided they needed something that was low maintenance and comfortable.

They also wanted somewhere that would fit in with their space and work requirements, as Susan is a musician and Michael a stained glass artist.

Since the 70s the couple had lived in a stone croft house in rural Aberdeenshire – which they state often felt “freezing cold.” Susan says: “As you’re going to be at home all the time, you need to be comfortable, not forever stoking fires.”

The couple felt they needed something that acted as a hybrid of home and workspaces. “My husband, who makes stained glass windows, was working out of the garage at our previous house.

It was freezing, so he was looking for somewhere with a design studio and an area where he could construct his windows,” says Susan. “I was an accountant all my life, but I’m also a musician. In retirement I wanted to play music and have people over to play. So, I was looking for a music studio. We search and searched for premises all over Scotland, but couldn’t find anything that suited us.”

Building on their own land

After a fruitless search, the couple changed direction and decided to look closer to home. Much closer. “Given that we had nine acres of land, we decided that it would be worth trying to to see if development was possible and if we could get planning permission,” says Susan.

The Zapperts wanted an efficient and modern property, and chose a Scandi-style timber frame house, delivered by Fjordhus

“The general principle is not to allow ‘living development’ in the countryside, outside villages. We were expecting them to say no, but they didn’t.” The couple were delighted to secure outline planning permission – largely thanks to support for the project from local residents.

Spurred on by this unexpected but welcome outcome, the couple went to a building show and met specialist timber frame house builder, Fjordhus.

Read more: Scandinavian Style House Design Guide

They loved the style and details on offer, and consequently, Fjordhus invited architect Stuart Davidson, who is Scottish Borders based, to visit the couple and discuss the design of the couple’s proposed home.

- NAMESSusan & Michael Zappert

- OCCUPATIONSRetired Accountant / Musician & Stained Glass Artisan

- LOCATIONAberdeenshire

- TYPE OF BUILDSelf build

- STYLEModern Scandinavian style

- METHOD OF CONSTRUCTIONTimber frame

- HOUSE SIZE422m2 (includes a 110m2 garage)

- PLOT SIZE6 acres

- LAND COST Already owned

- BUILD COST £633,500

- COST PER M2 £1,501

- BUILDING WORK STARTED November 2017

- BUILDING WORK TOOK13 months

“We didn’t want a box for a house,” says Susan. “My husband wanted to be at the south end of the site, and the last thing that I wanted was sun to be on my instruments, so I wanted to be at the north end. It’s not that we don’t want to speak to each other!

We also gave guidance in terms of the size of rooms – we didn’t want massive bedrooms, but we did want a big open-plan living area. I gave dimensions for my music room; one of my harpist friends advised about the ideal size, in terms of acoustics and a space that would allow enough people in to enjoy the music.”

The open-plan area houses the kitchen, dining room and living space. The coupe say this is where they spend most of their time together

Stuart’s solution was to build a central house with two wings on either side. “The clients were very clear about their brief,” says Stuart. “So, we looked at it as a house in two parts. We actually flipped it around so that the harp studio was located to the southerly public frontage, because you had students and visitors coming in.

The stained glass studio was then linked into the more utilitarian north facing side of the house, with the garages and such like. The idea being that the working parts of the house were all located and linked together. The house, in a way, is like an air lock in between the two wings.”

Creating a stable internal atmosphere

Creating a stable environment in terms of moisture and temperature control was crucial to the success of the house. There was much to account for in terms of of Susan’s fragile instruments – four harps and a baby grand piano – and Michael’s workspace that features a glass kiln.

Although an attractive feature, the couple don’t often use the woodburner, as the house is so well insulated and warm

“The idea behind the harp studio was to use the sloping site and create a vaulted ceiling, not only for acoustics, but also to control the temperature. If there was overheating, it would be dragged up to the top and removed via the rooflights, which act as a natural exhaust. All windows and rooflights are also positioned to allow soft dispersal of light that won’t affect the harps,” explains Stuart.

“The kiln in the studio was the trickiest challenge,” he continues. “As a result we designed a two-storey studio with an open staircase, which naturally balances that zone and allows air to circulate.

There is a glass link from the studio to the house, acting as a thermal break where no kiln heat transfers when opening the door from the studio to the kitchen. It also removes noise from the kiln to the main house.”

The main central body of the house features, at ground level, an open-plan kitchen dining area leading to a double-height lounge and a separate study/bedroom. Upstairs are three additional bedrooms, with a lounge area at the top of the stairs.

The kitchen, from David Douglas, is the hub of the home and a core part of the open-plan zone in the main section of the house

“When we’re not working we spend a lot of time in the main kitchen area and also the snug – which is technically the downstairs bedroom that we currently use as our TV room,” says Susan.

Design and materials

The house design relates directly to the sloping site – there is a strong boundary wall and the Zapperts were keen to gain views up and over that. Stuart explains: “We designed a stepped structure that benefited from views into the landscape and into the woodland, while at the same time gaining the protection of the wall and prevailing wind. We worked with the planners on our amended plans.”

The stepped design has been a huge success. “The house is at the top of a hill and the builder suggested that we move the house down a couple of metres,” Susan continues.

The house boasts a bespoke oak staircase, with open treads and glass balustrades. It leads up to a mezzanine-style lounge area, overlooking the open-plan space below. The lounge benefits from unobstructed views through the gable window

“We have a field next to us and if we went down we wouldn’t get so much wind. The builder also suggested a bracing bar on the window to the west, which is where the prevailing wind comes from, to make sure that it was safe. This has all worked well.”

In terms of materials, the rural setting dictated external features such as the larch cladding, stone with some render and a natural slate roof.

Internally engineered oak floors, solid timber doors and the open bespoke oak staircase give a warm, natural feel. Ceramic floor tiles, sourced by Michael and Susan, are used in the high traffic areas, as such as the kitchen and bathrooms.

In terms of construction, the house is prefabricated timber frame, which sits above the concrete slab foundations. “The build itself was really fast. It went up really quickly and was a joy to watch,” says Susan.

We Learned…

|

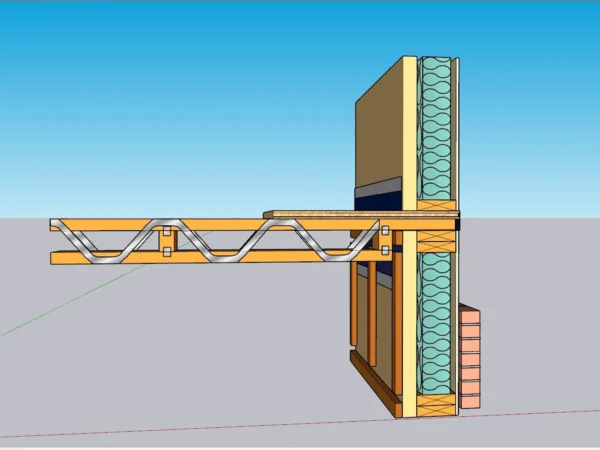

The frames are super insulated, with 195mm thick Frametherm 40 fitted between the studs of the external wall panels.

There’s also a further continuous layer of 25mm rigid polyurethane insulation to prevent thermal bridging and improve the U-value, and finally there’s a layer of Glidevale VC Foil Ultra silver foil. A service void was created internally with sealed and taped joints.

Moving in

The couple lived nearby during construction; they sold their house before work started and moved around 10 miles away to a rental property. “We came by everyday to see what was going on, but would not get in the way,” says Susan.

The master bedroom is light-filled and airy, thanks to its high ceiling and ample glazing

“Prior to the build we did have to cut down trees. We also had to install services up to the house from the main road – around 250m. The water had to come across from the other side of the main road.”

Since the Zapperts moved into their new home it has performed perfectly on every front. “The constant temperature in the house works beautifully. We have a woodburner, but we don’t really need it, it’s just for back up,” says Susan.

Read more: 10 Ways to Stay on Budget with a Timber Frame Home

“We really like our house and work spaces. The harp room looks out the garden, which is beautiful. It’s a lovely social space.

Kids can come along to practice for their music exams. And if I want to have half a dozen people over to make music it works very well. The house has everything, when we were in lockdown we didn’t feel deprived at all.”

Login/register to save Article for later

Login/register to save Article for later