MVHR System Design and Ducting Options

As houses have become more airtight, in some cases far surpassing Building Regulations standards, there is more of a need for whole-house systems that provide mechanical ventilation.

These are now replacing conventional methods, such as trickle vents and individual extractor fans in moist areas like kitchens and bathrooms.

Mechanical heat recovery, which works hand-in-hand with whole-house ventilation, is a way to provide a fresh supply of air in our homes that has been pre-warmed using recovered heat.

Learn more: Mechanical Ventilation & Heat Recovery FAQ

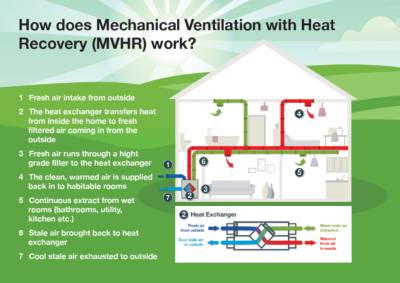

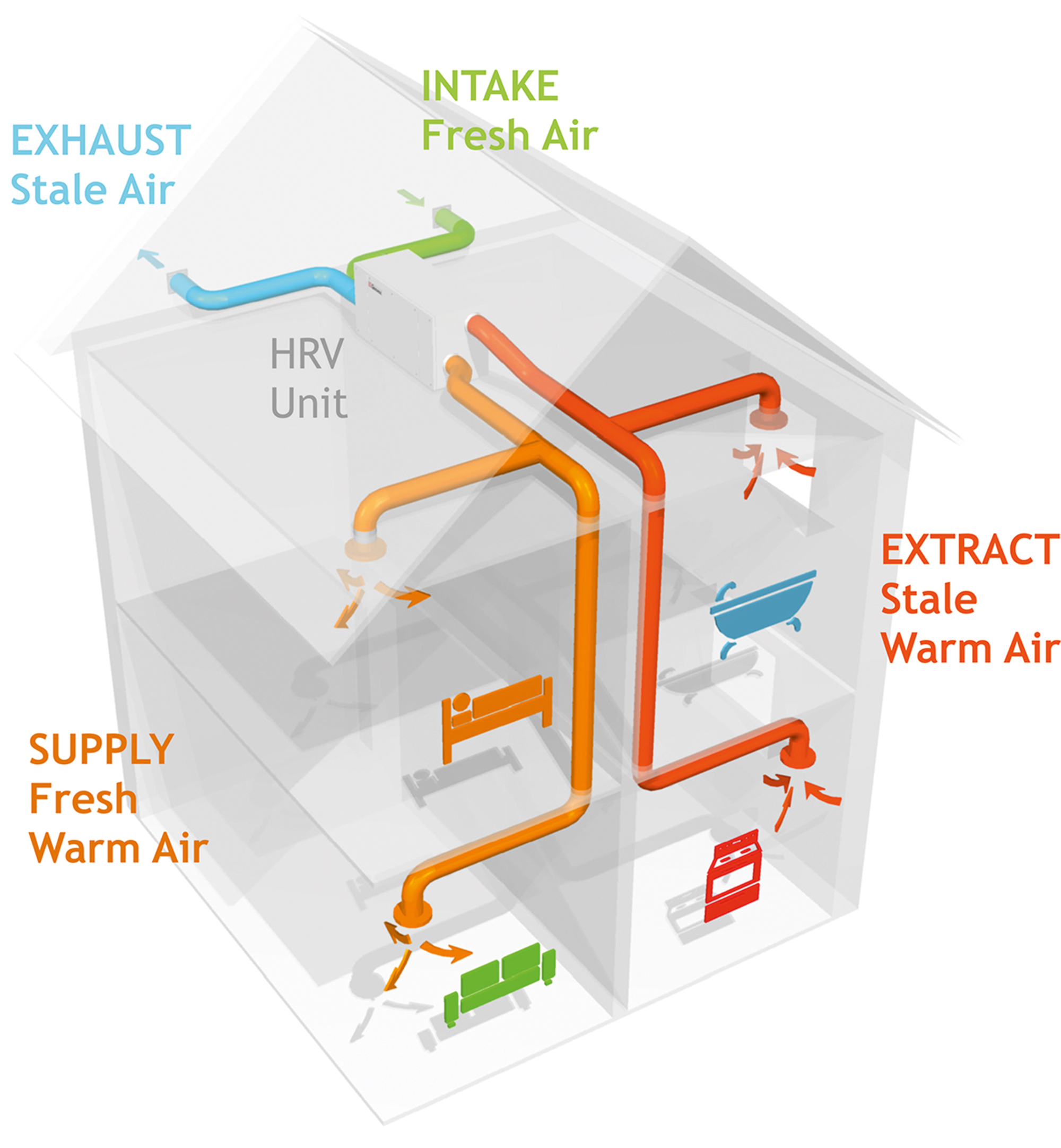

The systems are designed to permanently extract moist, stale air from our wet zones on a trickle basis while distributing fresh, clean air from outside to our reception spaces at the same balanced rate.

The two air flows merge in the heat recovery unit but crucially do not mix; instead, they are separated by the heat exchange unit which allows warmth to flow from the outgoing air into the cooler incoming supply.

Need heating advice?At Build It Live there are free seminars that discuss the main heating options, free expert advice in the Heating Advice Clinic and you can discuss the pros and cons of the various options with an array of heating exhibitors. Explore all the options, all in one place – only at Build It Live. Build It Live takes place three times a year in Kent, Oxfordshire and Exeter. The next show will be on 8th and 9th June 2024, in Bicester, Oxfordshire. Claim a pair of free tickets today and start planning your visit. |

How MVHR works

A mechanical ventilation and heat recovery (MVHR) unit will usually contain two fans; one to push fresh air through the heat exchanger and the other to pull the wet stale air through a separate circuit.

This diagram from Total Home Environment shows the basics of how an MVHR system works

An MVHR system recovers about 75% of the heat that would otherwise have been expelled outside. Putting some basic numbers to this, if the temperature was 0°C externally and 20°C inside our house, then, at the 75% recovery rate, we would expect to distribute fresh clean air to our reception spaces at somewhere around 15°C, meaning that only a small top-up would be necessary to maintain optimum internal conditions.

This technology is not a primary source of heating, but instead an incredibly efficient way of introducing fresh air without the need to bring it all the way up to temperature. It complements other energy efficiency strategies and works best in homes where insulation, airtightness and efficient primary heating have all been carefully specified.

The Zehnder ComfoAir Q, from Paul Heat Recovery, is controllable remotely via iPad and iPhone

In particularly cold temperatures there are optional heater elements on some systems that can help to warm the supply air if need be. For the summer months, a summer-block can be used to bypass the exchanger; some setups also route warmer fresh air through ducts buried in the ground so that this can be naturally cooled before internal distribution.

If you’re prone to opening all the windows and doors in the really hot summer then the system will obviously be somewhat marginalised during that period of the year.

How to design an MVHR system

Part F of the Building Regulations (which covers ventilation) states that any mechanical systems installed must be commissioned and tested for compliance.

Thankfully there are plenty of specialist companies that manufacture and supply compliant MVHR systems and they will happily undertake the design work for you. They will need a set of floorplans, including elevations, so that they can carefully work out internal volumes.

An EnviroVent installer fitting an MVHR central unit

Using the minimum and maximum flow rates listed in the Building Regulations, they will quickly assess the ducting diameters required to connect all spaces together.

A key design criteria is where your central unit is to be located. This is the box with the heat exchanger and fans inside and all ducts will need to lead to and from this unit with four entry and exit positions. It’s usually the size of a small chest, and a dedicated cupboard or a part of your attic void is the most sensible location.

The loft is an ideal spot to site the central unit; ensure there’s access around it for ongoing maintenance. This system is by Rega Ventilation

The unit will need to be accessed for routine maintenance, as the filters that protect the air supplies entering the unit need to be changed and/or cleaned from time to time.

Smaller systems exist that can be installed in the equivalent of a wall unit in a kitchen but their capacity and performance is much more limited.

Ducting options

There are four ducts that connect to the unit. These are for the incoming supply, bringing fresh air from the outside; the distribution of fresh air internally to the habitable rooms; the extraction of stale air from the wet rooms; and the extraction to the outside.

MVHR in a Passivhaus HomeWhen architect Bernard Tulkens of Tectonics Architects decided to self-build his own home in Hackney, East London, he was keen to create an energy efficient new Passivhaus home. However, surrounding buildings overshadowed the tight site rendering it impossible to benefit from southern sunlight, which reduced the possibility of passive heat gain. Bernard worked with Peter Ranken from Accredited Passivhaus Design to come up with a solution. They employed Green Building Store to design and supply a mechanical ventilation and heat recovery (MVHR) system for the scheme. This unit was critical in creating an overall setup that met the Passivhaus standards that Bernard aspired to. “The Novus 300 unit was the only MVHR system that offered the efficiency needed for Passivhaus certification. Its quiet operation was also a benefit, as it’s located in a cupboard off the main living space,” says Peter. “I was initially concerned about the noise of the system but that proved not to be an issue,” adds Bernard. “The setup is very quiet – we can’t hear it at all.” Medium to large PAUL Novus 300 systems are suitable for floor areas between 40-300m2 and offer a heat recovery rate of 94.4% at 145m3/h. The unit in this project utilises rigid spiral-bound steel ducting, which has been left exposed to suit the industrial-style decor. “The MVHR system is very easy to operate and maintain, plus the air quality is fantastic,” says Bernard. “The blueprints by Green Building Store’s MVHR Design Service were well thought through, well organised and made a lot of sense.” The finished property’s impressive energy-efficiency credentials led to it winning the Urban category at this year’s UK Passivhaus Awards. |

These ducts, many of which are insulated, are very space hungry, which is why their location needs to be carefully planned.

There are a number of different ducting options. Galvanised steel is probably the most robust but also has the longest installation time and will need to be lagged with insulation. The easiest installation is with corrugated flexible ducting, which can also come pre-insulated, but is easily crushed, either during installation or when retrieving Christmas decorations from the attic! Constricted ducts will affect the performance of your system.

EnviroVent’s EnergiSava 300 has a range of options for connecting the ducts; it’s shown here with flexible plastic ducting

Rigid plastic ducting is also available; this can be rectangular in section, which assists with certain difficult runs.

For two-storey properties, you need vertical duct runs, which can connect the ground-floor ceiling with the first-floor ceiling, as well as horizontal ducts in both attics and intermediate floor locations. Planning this layout well in advance can eliminate disappointments when recesses, wardrobes or room symmetry become potentially compromised.

Ducts also need insulation, so as not to lose valuably recovered heat in cold attic voids and also to prevent condensation where warm moist air is travelling through cold attic voids.

Condensation is, however, inevitable, which is why all systems must have a condensate drain leading to the exterior from the main unit.

Login/register to save Article for later

Login/register to save Article for later