Internal Fit-Out: Kitchen & Plant Room

There are 4 steps in this guide

One of the things we’re keen to show with our interior fit-out choices is that it’s possible to achieve a wow-factor look on a typical self build budget.

For instance, if you want an all-singing, all-dancing kitchen and money’s no object, you can happily drop £30,000, £50,000 or sometimes much more on a beautiful bespoke design. But with a bit of creativity, it’s possible to spend much less and still create a space that will be the envy of friends and neighbours.

This all comes back to our ‘chunks of £5,000’ theory. Most of us have finite budgets to work with, so it’s vital to get the big decisions right and sink your cash into the elements that matter to you – while aiming to maximise value for money.

Howdens prepared a number of 3D visualisations of our Balham Gloss kitchen to help us finalise the setup.

To that end, we went around some of the main DIY sheds to source ideas and prices for the Education House kitchen, including the likes of Ikea, Wickes and Howdens. Our idea was to keep carcassing costs down by opting for an off-the-shelf range, but then upgrade it with elements such as customised worktops, sinks and flooring.

In the event, we found that our local Howdens in Bicester offered the balance of service, quality, design flexibility and price we were looking for in the kitchen. And it made sense to use them for the more understated utility cabinets in the plant room, too. Howdens usually sells to customers via contractors, so you rarely know the list price (only the figure your trade is charging) but the value is plain to see.

Planning the kitchen

There’s been a big trend in recent years towards handleless kitchens. Sometimes these can look a little too spartan, but Howdens’ Balham Gloss range avoids that with some interesting upgrades.

It has a monochrome vibe – but we’re teaming them dove grey drawer and door fronts for a touch more character. It’s part of Howden’s Linear range, which mimics the minimalist straight lines of some of the very expensive German brands. It’s much cheaper, but still comes with a whopping 25 year guarantee – and our builders have installed many Howdens kitchens and never had a callback!

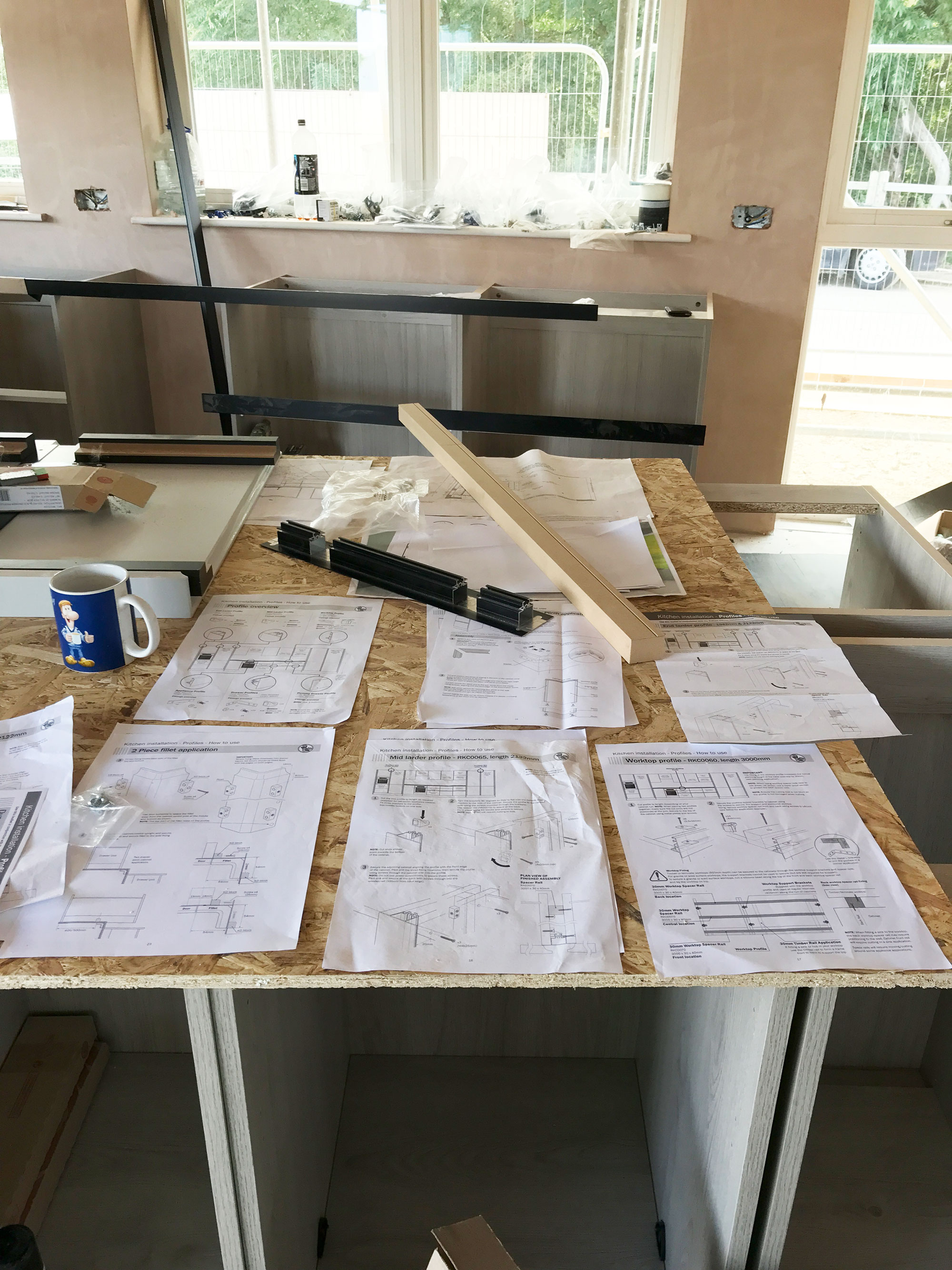

Most joiners have experience fitting Howdens kitchens – but the Balham design has some unique elements, with a big set of instructions, so it’s a bit more involved than usual. The finished look, however, will be worth the wait

With so many windows in the open-plan zone, we’re limited on space for wall-hung cupboards. So we asked Howdens’ design team to focus on floor-standing storage and worktop space, with a large L-shaped zone running into three full-height units near the big IDSystems sliding door. These will host built-in appliances (including a fridge/freezer, microwave and oven) and a dedicated larder cupboard.

To break up the space, we’ve specified an island unit, which we’re upgrading with a waterfall-style quartz worktop from local firm The Granite House.

A 300mm oversail on the side nearest the dining area will provide a handy breakfast nook, while the island will also accommodate a hob with downdraft extractor (so we don’t need a clunky unit up top), as well as extra storage. It should work brilliantly for hosting, too, providing a spot to serve canapes and the like.

From the Education House side of things, it will be the perfect spot for visitors to go over their house plans with Graven Hill’s team.

Most of the kitchen will be fitted with deep soft-close drawers rather than standard door-fronted cabinets. Another modern trend, this works much better for storage, as they can be pulled out fully to allow you to easily see everything inside – rather than fishing around in the back of rammed cupboards.

The carcassing is now in place, and Barry has started to assemble most of the drawer units

It also underpins the linear effect. A little bit more material (and time) goes into drawers, however, which does lift the price slightly compared to door fronts.

Barry, one of Drewett and Hunt’s regular chippies, is installing the units. The edging strips and the acute angle in the corner of the main run make it a slightly more complex job than fitting a standard kitchen into a square room. But Barry was proactive and made a visit to the local branch to talk through anything he wasn’t sure on before getting started, and the carcassing work is now complete.

Wow-factor worktops

The Granite House recently attended site to template the Caeserstone White Attica quartz for the island and Silestone Marengo (a darkish grey) worksurfaces for the main run – and this turned out to be a valuable learning curve.

We’d assumed we just needed our undermounted sink on site as a reference, but it turns out you need it installed into the units and have your tap available, too, so that they can check everything works together properly. You don’t want them cutting out the hole for the sink, only to find it needed to shift 2mm forward because the tap levers are touching the wall – or slightly to the side to avoid drawer runners.

We hadn’t realised we’d need to install the sink before The Granite House can accurately template for the worktops. We may need to recess this slightly into front support timber

It’s a bit easier to get away with not having the hob fitted, as we know the exact cut-out size (680mm wide x 480mm deep). It’s also going into the island unit, so there’s more flexibility with its position – but we’ll have it central, and set 60mm back from the front edge of the quartz.

With the sink not yet in, Tim from The Granite House was happy to come back later in the week to template up in one go (in fact, I’ll be on site tomorrow to meet him). But it wasn’t a totally wasted visit, as we were able to iron out a few key details.

For instance, Tim suggested a recessed drainer to the left of the sink, so it oversails the dishwasher (where most people will be resting pots, pans etc). We also agreed on a 25mm overhang for the quartz – slightly more than the drawer fronts, but this means that if anything comes out of alignment in future, it will still look right. The corners of the surfaces will have a 10mm bevel for safety.

For the waterfall worktop, which will run down the sides of the island (stopping just short of the floor), we were able to simplify the detail slightly. Tim explained that the silicone that bonds the quartz to the cupboard is so strong, we don’t really need the metal angle bead we expected.

We can just pack out with timber and remove this when the bond has gone off. We marked out the exact position of a double socket in the side of the island, too. One thing we do need to do is screw the island to the floor. That way we can be sure it won’t go out of square before the worktop’s fitted – or move if a teenager decides to sit on the breakfast bar!

Plant room fit-outProgress rumbles on in the plant room. Pete from Total Home Environment has almost finished his first fix, and the ducts he recently ran through the internal block wall have now been fully waterproofed by Surrey Basements. There are still a few connections to be made here that are stopping us closing up the zone with plasterboard, but these should be sorted imminently. Meanwhile, the Moss Technical team is 99% there and has installed the racks where the Niko Home Control hub will go. We’ve also come up with a novel approach for Nu-Heat’s underfloor heating manifold, creating a recessed area in the stud wall to frame it and give visitors instant access – another nod to our Education House approach. There’s a lot of ductwork on this side of the plant room, including near ground floor level. So the chippie working here, Rob, has had to painstakingly cut away some of the internal carcassing to slot everything into place. He’s also reinforcing this whole run with extra timber framing. On the other side of the L, there will be a sink, space for a washing machine and a larder cupboard. The plant room units are Howden’s Greenwich Gloss, with grey oak carcassing. We’re going with dove grey door fronts to complement the kitchen, but give you a immediate sense of the difference compared to using drawers. As this is a functional zone, it will have more of a utilitarian feel, with stainless steel-effect T-bar handles, 38mm-thick laminate worksurfaces and easy-clean white wash oak vinyl flooring. |

Login/register to save Article for later

Login/register to save Article for later